Inside Algood is a behind-the-scenes look at how engineering, manufacturing, and people come together to build the casters you rely on. In this issue, we spotlight our tool and die centre.

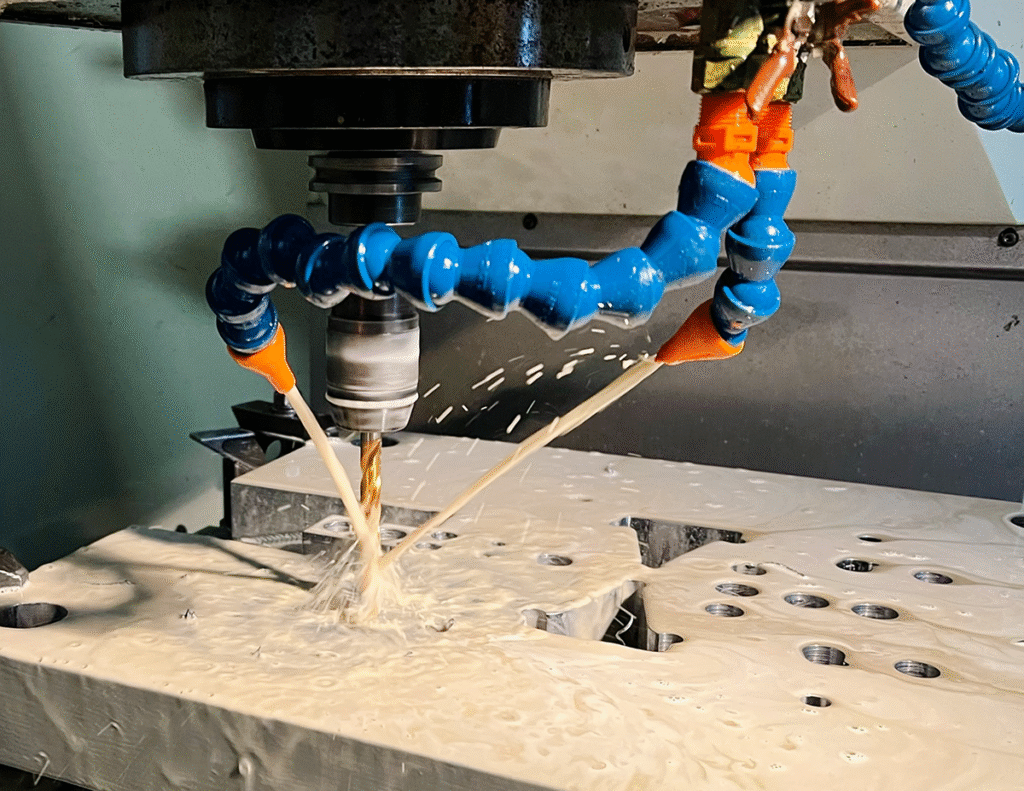

The tool and die centre is a foundational component of Algood’s fully integrated manufacturing facility. In fact, Algood is the only major North American caster manufacturer with an in-house tooling area. Absolutely all our tooling is done onsite, supported by CNC lathing and milling, 3D printers and other sophisticated equipment.

The name “tool and die” reflects two sides of the same craft. Tools hold, guide, and support parts during manufacturing, while dies shape material into precise forms. Both live side by side in this department and are essential. Together, they determine how parts are formed, how repeatable the process is, and how well those parts perform once they become part of a complete caster.

The tool and die department is where raw metal is first shaped into the tools that ultimately form a caster. Long before anything is assembled or tested, this is where the groundwork is laid. The tools and dies built here quietly shape the accuracy, consistency, and reliability of every component manufactured at Algood.

The tool & die area supports metal stamping by developing the forming that leads to yokes and steel components and supports injection moulding processes by creating the moulds for wheels, brakes and all plastic parts.

All machining, milling, and CNC tooling work is done in-house. Mould design engineers constantly design and refine moulds for both stamping and injection moulding. Having this capability under one roof means ideas move quickly from concept to reality. When components are being developed, or an adjustment, refinement, or repair is needed, it happens right here and right away. We don’t have to wait for outside vendors or ship tooling there and back. That hands-on control helps keep projects moving and lead times in check.

The integrated tooling area also encourages ongoing internal collaboration. Engineers, toolmakers, and production teams work closely, consulting on the best possible solutions and resolving potential issues before they ever reach the production floor. The focus is on stability and repeatability, building tools and dies that support long production runs.

Our tooling supervisor sees the department as the “mother” of all production because top-notch forming and moulding lead to top-notch casters and components. Tool and die work plays a direct role in quality. Well-built tooling supports tighter control and reduces variation, which is critical for parts that must fit and function together. Having tooling onsite increases responsiveness and minimizes delays. It allows us to guarantee superior quality, attractive lead times and dependable delivery dates.

For customers, this entire operation stays behind the scenes. What they experience is consistent fit, dependable performance, and products that arrive ready to work. Tool and die making may not be visible, but it is critical in guaranteeing the quality our customers have come to expect.

Algood is proud to manufacture its casters and wheels right here in North America. With our fully integrated manufacturing facility in Toronto, we are leaders in quality and innovation. For more information about Algood Casters, Call: 1-800-254-6633 or Email: Service@Algood.com