Customers often ask us whether they should order an integrated wheel and swivel lock or separate brakes and position locks. There are a number of considerations, and it can be complicated. So, in this issue of CasterU, we break down the differences between brakes and swivel locks so that you can make better-informed decisions.

There are times when it’s beneficial to prevent a caster wheel from turning while also preventing the wheel from swivelling. For example, serving carts used on airplanes require added stability to protect them from turbulence. For lighter capacities (under 1,500 lbs), our iLock™ wheel with directional lock or our DLB – double-locking brake are ideal solutions.

However, there are applications with larger capacities that require both a swivel lock and a brake. Brakes apply friction to the wheel to prevent the caster from moving, while swivel locks keep a caster from swivelling.

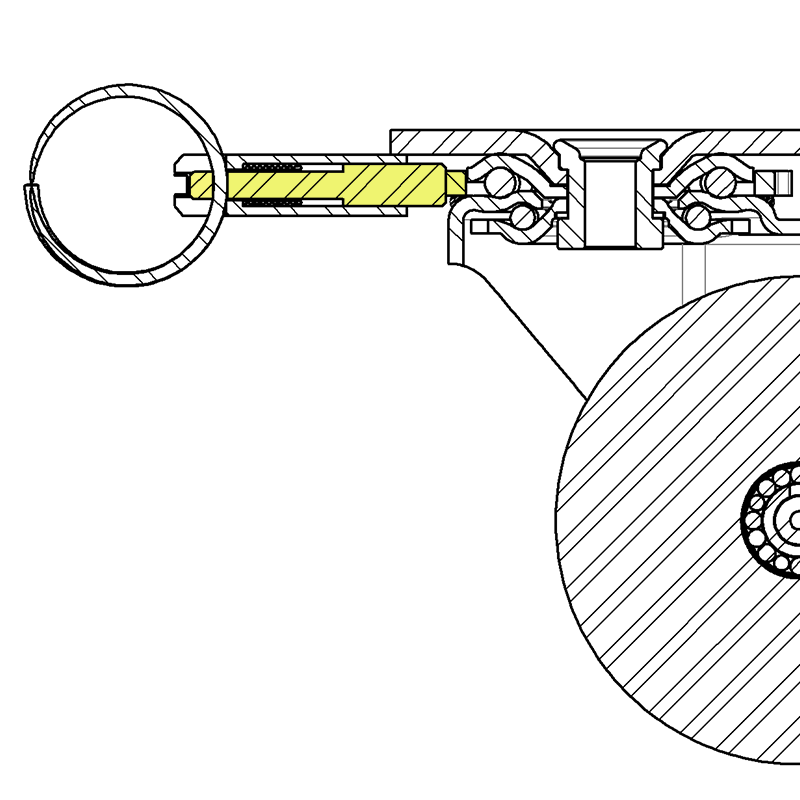

Essentially, a swivel lock converts a swivel caster into a rigid unit. A hand-operated plunger engages with a notch in the raceway to prevent the caster from swiveling. A 4-position swivel lock can be engaged at any 90-degree interval. The swivel lock mechanism can be purchased pre-welded to the top plate or with wings that secure the PSL to the plate when using mounting bolts.

Wheel locks offer operators greater flexibility when moving and positioning carts and equipment. They enable movement over long distances, where two rigid casters and two swivel casters are ideal. With the wheel locks disengaged, the equipment can then be easily maneuvered in tight spaces or precise positions. Additionally, wheel locks enhance safety in situations that require absolute immobility and control. They also provide added stability by eliminating the flutter often associated with rigid casters.

Wheel locks are particularly beneficial for heavy loads where the weight makes it difficult to engage a double locking brake easily. Capacities of 2,500 lbs. or more are especially appropriate. Common applications include food processing, automotive carts and aeronautic engine cradles. We custom-manufactured a caster featuring both horizontal and vertical wheel locks to transport jet engines. Other uses encompass medical equipment where precise positioning is vital (e.g., surgical equipment).

The decision regarding which brake or position/swivel lock to order isn’t always clear-cut. But what is absolutely certain is that our brakes and locks are manufactured with the precision and quality you can trust. You can also be sure that we are here to help you configure and implement the best possible caster solutions. Contact your local Algood representative or a member of our customer service team.