I monitor economic news and insights very closely. It’s part of my daily media routine and there are several people whose opinions I seek out and follow. Based on all that, there are three interconnected E’s that are keeping me awake lately. The situation in Europe, the impending global energy crisis and the economy all have my full attention these days. I’m concerned but I’m also very confident that Algood’s manufacturing will remain strong.

Europe’s supply of gas has been cut off by Russia and the effects are rippling through every country. Electricity supplies may not be enough to sustain the winter. In some places, raw material production and manufacturing is being shuttered. Production of everything from manufacturing components to toilet paper is being reduced. Not surprisingly, both unemployment and prices are soaring.

Algood ships worldwide, including to Europe and some of our components are manufactured in Europe. Both of those factors may present a challenge to our business over the coming months. In addition, what happens in Europe does not stay in Europe. There will be global repercussions to the current state of European affairs.

Gasoline and oil prices in North America peaked about six weeks ago but in California, there is a severe energy crisis. The Californian electricity grid can’t keep up with the demand and electricity imported from other states is not enough to close the gap. The state is re-evaluating its decision to mothball nuclear power plants. All of that makes the state more dependent on fossil fuels. While Russian oil represents only three percent of total imports to the U.S., nearly half of Russian oil shipped into the U.S. last year, or close to 100,000 barrels a day, ended up primarily in California, Washington and Hawaii. And California’s economy is the largest in the U.S. and the fifth largest in the world.

California may be the canary in the coal mine. We can expect extreme weather to put demands on energy grids throughout North America. While oil prices have been declining, reductions in global supply will reverse that trend. Rising energy costs will affect every type of production, having an impact on supply chain, employment and the cost of goods.

That brings me to E number three – the economy. The inflation rate is high. While the cost of some goods like steel, wood and paperboard have started to come down the cost of other supplies and components is rising, hurting manufacturing. Central banks in the U.S. and Canada are increasing interest rates with no ceiling in sight. While experts debate about whether the economy is officially in a recession, the economic outlook gets bleaker. Stock markets are losing value. A recent PwC study indicated that 50% of firms in the U.S. are forecasting layoffs. The future is, at best, uncertain.

A number of our suppliers and customers reducing output and laying off employees. We expect that supply chain issues will persist for both manufacturers and consumers. The impact on sales is unclear but it’s unlikely that our revenue will not grow this year.

Our employees have always been our most important asset and we are concerned for them. The cost of food, clothing and other items is increasing rapidly, straining personal budgets. Families are being forced to do more with less which increases stress levels.

We have faced tough situations before and not only did we survive, we thrived. In 2008, we didn’t lay off a single employee and made a decision to reinvest in our business. Over the past two years, we very successfully guided the company through the pandemic and emerged stronger.

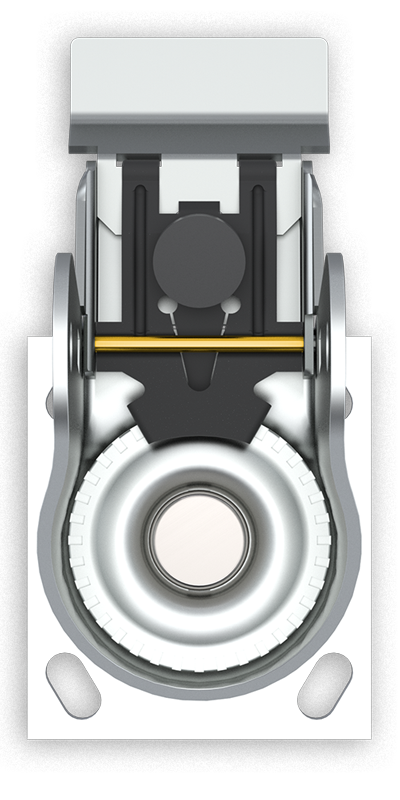

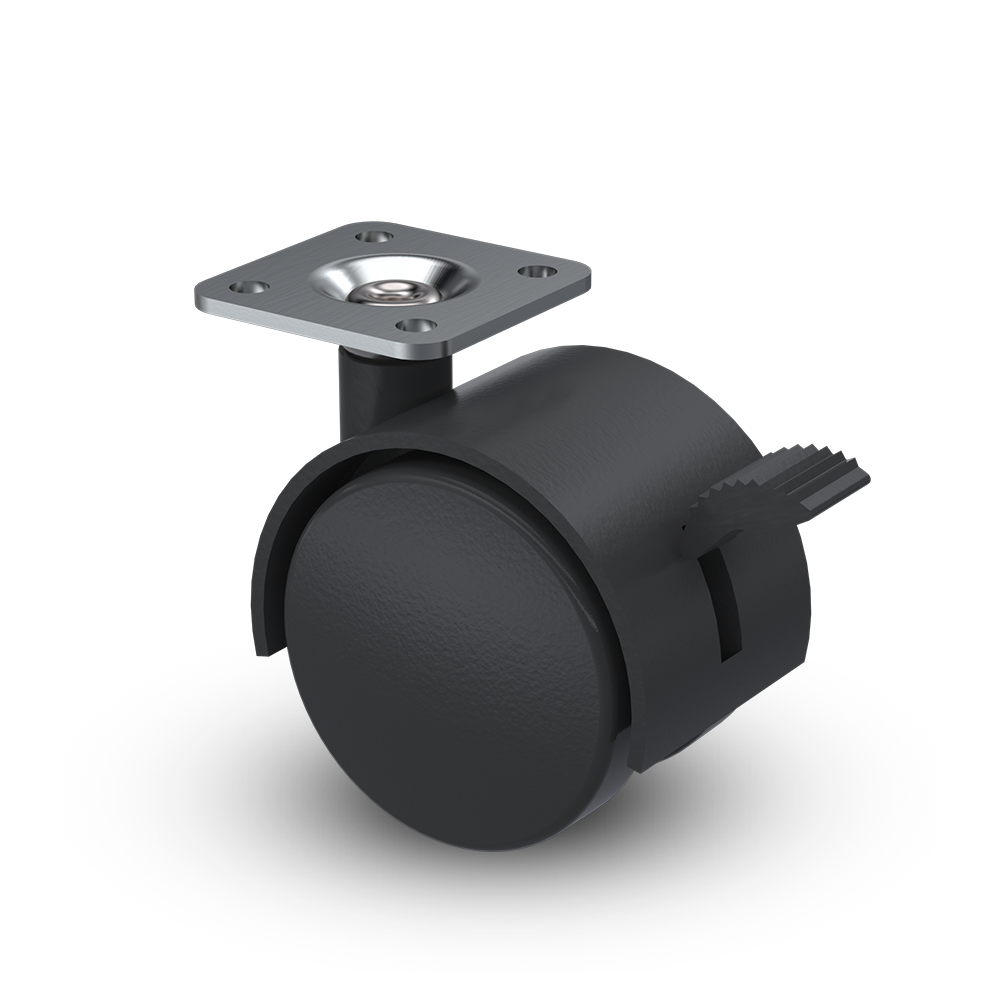

Throughout it all, we have grown by being responsive to the needs of our customers. We have innovated by bringing new products to the market and by finding unique solutions to meet customers’ requirements. The quality of every caster and wheel that leaves our plant is guaranteed and our reputation for on-time delivery is unmatched.

Despite my concerns, I am confident that none of that will change. We are moving forward with product development projects and capital equipment acquisition. I am watching these three Es – Europe, energy prices and the economy – very closely. But I’m also ensuring that we will be there for our customers and remain the next generation of CasterSmiths.

I’d like to take this opportunity to wish all our Jewish customers, colleagues and friends a Happy and Healthy New Year.

![6500 Series: S6563-A38H-RXW-RB-TG-ALK [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/08/Algood-Casters-6500_Series-S6563-A38H-RXW-RB-TG-ALK.png)

![0300 Series: 03T4-050-.375-16X.75HN [Black]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Casters-0300_Series-03T4-050-.375-16X.75HN.png)

![Mighty Maxx Series: S65253-B29F-RXW2-RB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/07/Algood-Caster-MIGHTY_MAXX-S65253-B29F-RXW2-RB.png)

![Lava WOW Wheel: W-7006-LVW-1.188 [Black]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Wheel-Lava-WOW-W-7006-LVW-1.188.png)