Zero Swivel Lead

The Rigid-Swivel Caster

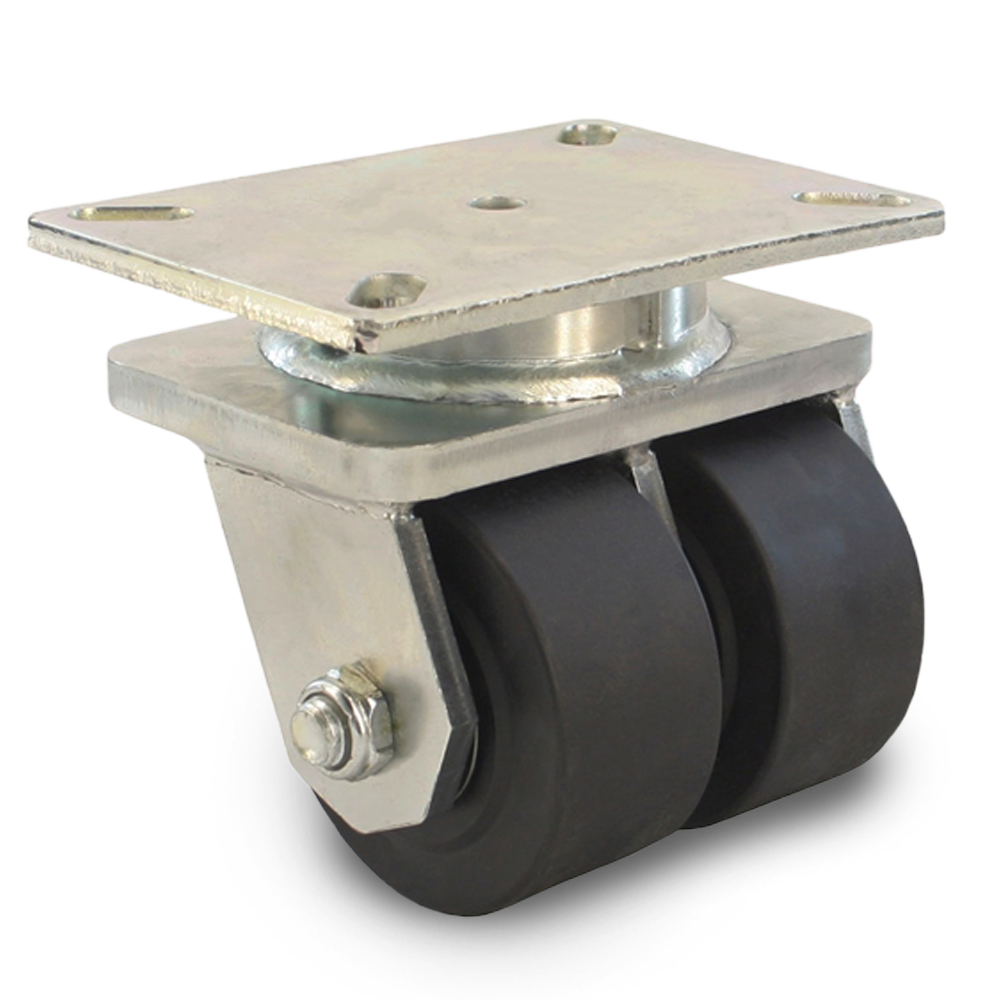

In the world of industrial mobility, one size rarely fits all. The demand for precision-engineered solutions has never been greater, and when off-the-shelf casters fall short, innovation steps in. Recently, an aerospace manufacturer needed a caster that could navigate tight spaces with absolute control, ensuring the seamless transport of high-value components. Traditional swivel casters lacked control, while rigid casters limited maneuverability—resulting in inefficiencies and misalignment. A solution was required that delivered perfectly controlled movement along fixed tracks without compromising load capacity or durability. That’s where the Zero-Swivel Lead Casters excels—engineered for precision, built for performance.

The Advantage of Zero Swivel Lead

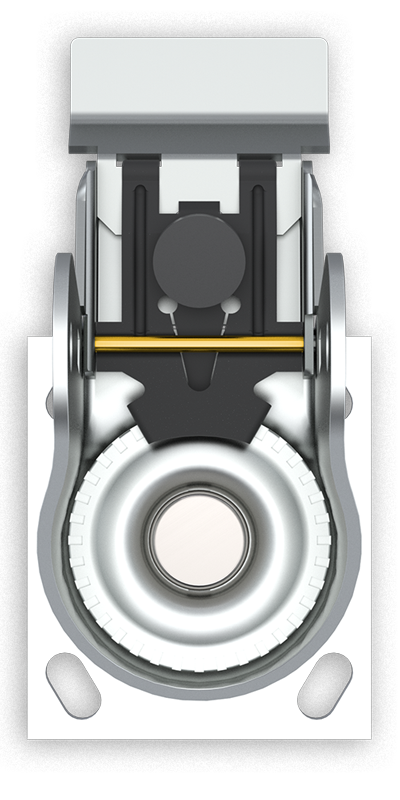

This unique design merges the maneuverability of a swivel caster with the alignment of a rigid caster, making it essential for industries that demand precision and controlled movement. Zero swivel lead casters are primarily engineered for sharp turns, increased maneuverability, and greater stability. These unique casters permit perfect 90º motion in any direction and add capacity because the head is always directly positioned over the wheel.

The design and production of this caster is made possible in Algood’s fully integrated manufacturing facility. Every component—from the robust kingpinless head to the precision-engineered v-groove wheels—is meticulously crafted to exceed industry standards. Our in-house manufacturing capability enables us to create custom solutions tailored to the unique requirements of customers and their engineering teams, across a range of industries.

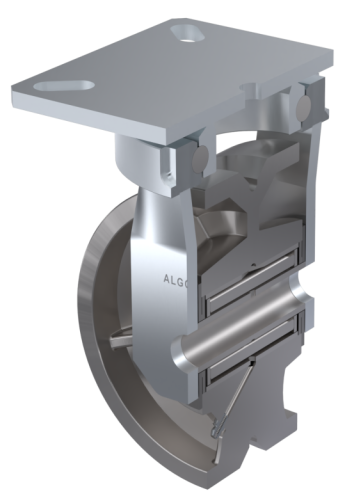

Sectional/Cut-Through

A sectional breakdown reveals this custom casters kingpinless raceway, which eliminates a common failure point, distributing impact forces evenly for exceptional strength and longevity. Unlike standard rigid casters, this custom Typhoon™ Caster is welded 90 degrees to the kingpinless head, allowing it to function as a swivel without a traditional swivel lead. This configuration enables precise 90-degree movement while maintaining structural integrity and load capacity. Paired with a cast iron v-groove wheel, it glides effortlessly on inverted angle iron tracks, delivering continuous, high-performance operation in demanding environments.

Industries and Applications:

Medical Laboratories – Guides racks seamlessly into autoclaves and sterilization chambers.

Aerospace & Manufacturing – Enhances controlled movement in high-precision environments.

Industrial Conveyor Systems – Ensures smooth, track-guided navigation in production facilities.

Automotive Assembly Lines – Supports material handling and transport in high-efficiency production.

Food Processing – Facilitates safe and controlled wash-down environments where hygiene is essential.

The NyRock™ Advantage: Customization at Its Best

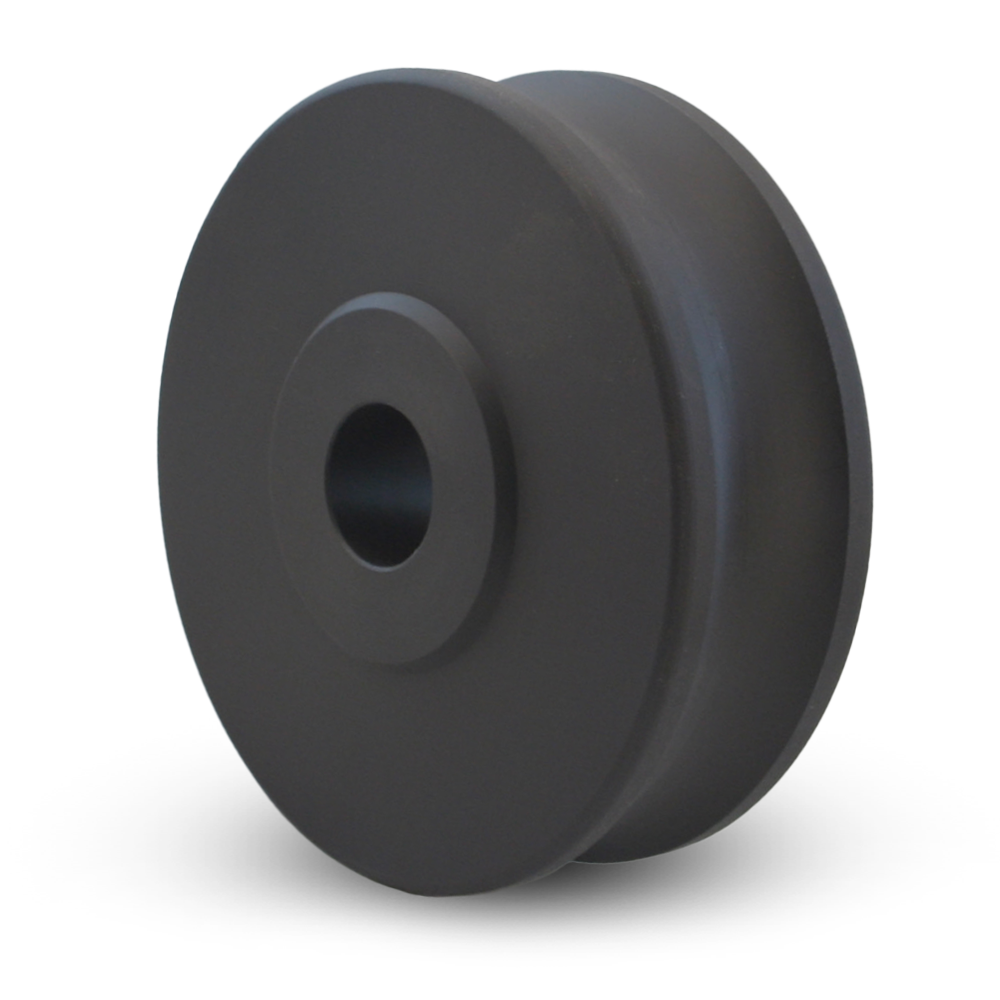

For specialized track compatibility, NyRock™ Wheels offer a customizable, high-performance solution. CNC-machined with customized v-groove or concave finishes, they ensure seamless integration across applications. Built for durability and efficiency, they provide high load capacity, smooth roll-ability, non-marking protection, and resistance to corrosion and moisture, extending equipment life in demanding environments.

Engineering Innovation, Delivered

With a fully integrated North American production facility, industry-leading engineering, and an unwavering commitment to quality, custom caster solutions are available to meet even the most complex operational requirements. We are the industry leader in producing unique caster designs to meet specific requirements. Connect with our team today to discuss your custom caster needs and discover how our innovative solutions can elevate your operations. Experience the Algood difference—where quality meets ingenuity, and your vision becomes a reality.

![6500 Series: S6563-A38H-RXW-RB-TG-ALK [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/08/Algood-Casters-6500_Series-S6563-A38H-RXW-RB-TG-ALK.png)

![Lava WOW Wheel: W-7006-LVW-1.188 [Black]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Wheel-Lava-WOW-W-7006-LVW-1.188.png)

![Zero Gravity Series: SSLTW82-A38H-LVW-RB-C [Zinc]](https://algood-casters.com/wp-content/uploads/2023/11/Algood-Caster-Zero_Gravity-SSLTW82-A38H-LVW-RB-C.png)