Custom Solutions and High-Volume Runs: The Algood Approach

When you’ve been in the caster manufacturing industry as long as I have, you learn one fundamental truth: success isn’t just about making a great product; it’s about making the right product at the right time—whether that means delivering a one-off custom caster or ramping up to mass production without missing a beat. At Algood, we’ve built our reputation by mastering the balancing act between customization and high-volume production without sacrificing the craftsmanship that sets us apart.

Customization and mass production are often viewed as opposites—one requiring flexibility, the other demanding efficiency. Many manufacturers see a zero-sum game where they must choose one over the other. At Algood, we reject that notion. We seamlessly integrate both custom solutions and high-volume production, delivering outstanding lead times and dependable delivery dates without sacrificing quality or craftsmanship.

Achieving this balance is no easy feat. It requires precise production planning and real-time adaptability. Our teams meet daily to refine production schedules and weekly to strategize engineering adjustments. Good lead hands—experienced professionals overseeing the manufacturing process—ensure that smaller custom jobs fit into our workflow without disrupting large-scale production runs. It’s a juggling act we’ve perfected into an art form.

Our ability to accommodate both custom and high-volume runs is directly linked to our fully integrated manufacturing facility. With an expert design and engineering team, an in-house tool and die centre, full stamping, injection molding, and CNC capabilities, as well as robotic welding and assembly—all under one roof—we possess both the production power and the castersmith expertise to meet our customers’ unique requirements. By investing in state-of-the-art equipment and the highly skilled personnel, we stay ahead of the curve and ready to scale production at a moment’s notice.

Many suppliers struggle with integrating custom manufacturing runs due to scheduling complexities or financial constraints. Custom solutions demand more time, skilled labor, and engineering expertise. However, at Algood, we put our customers at the center of our decision-making. Whether they need a small-run custom caster or thousands of pieces straight from our catalogue, we find a way to make it happen without compromising on quality or efficiency.

Customers often face the dilemma of choosing between a lower-cost, off-the-shelf caster and a more expensive custom solution. While the former may seem like the economical choice, it can lead to costly breakdowns such as equipment failures, floor damage, and prolonged downtime. We work closely with our clients to ensure they get the best value for their investment—both in performance and long-term cost savings.

Our dedication to meeting customer needs through adaptability is deeply rooted in our commitment to North American manufacturing. We believe customers should have the confidence that their requirements will be met right here in Canada and the U.S. That calls for the ingenuity, craftsmanship and commitment to quality that’s only found on this side of the ocean.

If you’re looking for a partner who understands the delicate balance between customization and mass production, you’ve found it. At Algood, it’s what we do best.

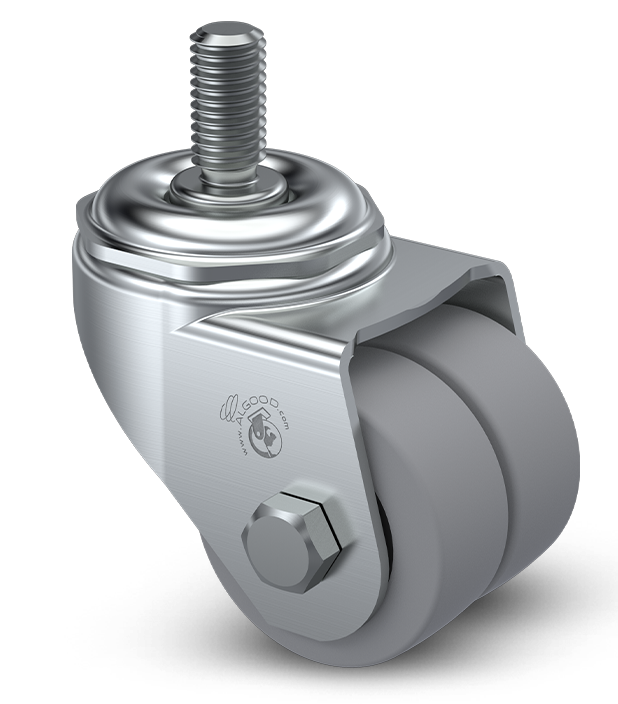

![1900 Series: S1953-A27D-PROF-PB-TG [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/08/Algood-Casters-1900_Series-S1953-A27D-PROF-PB-TG.png)

![1900 Series: S1953-A27D-LV [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/10/Algood-Caster-1900_Series-S1953-A27D-LV.png)

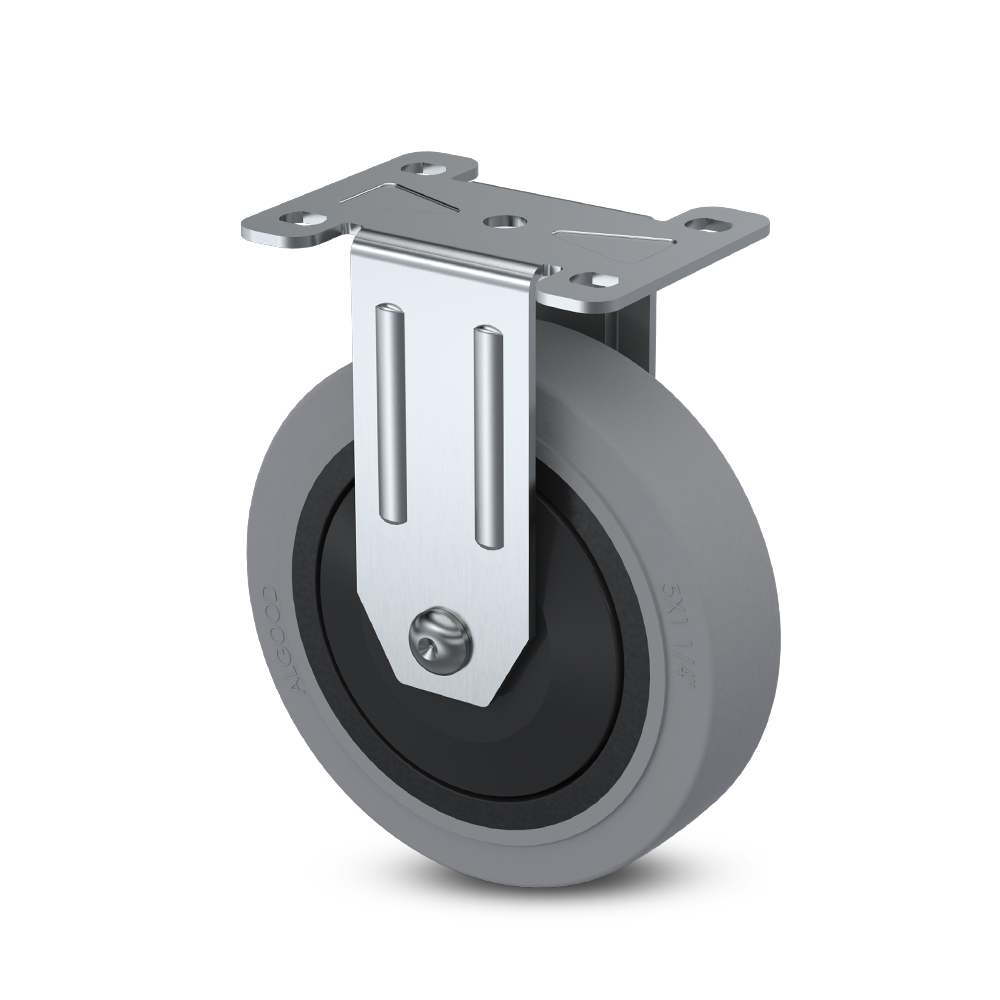

![5000 Series: S5053-A27D-HTPH [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/10/Algood-Caster-5000_Series-S5053-A27D-HTPH.png)

![5000 Series: S5053-A27D-PLY-PB-TG-iLK [Zinc]](https://algood-casters.com/wp-content/uploads/2023/05/Algood-Renders-5000_Series-S5053-A27D-PLY-PB-TG-iLK.png)

![NyRock Wheel: W-7006-NYX-PB-1/2 [Black]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Wheel-NyRock-W-7006-NYX-PB-.5.png)

![NyRock Wheel: W-7006-NYXCC-PB-1/2 [Black]](https://algood-casters.com/wp-content/uploads/2024/07/Algood-Wheel-NyRock-W-7006-NYXCC-PB-.5.png)

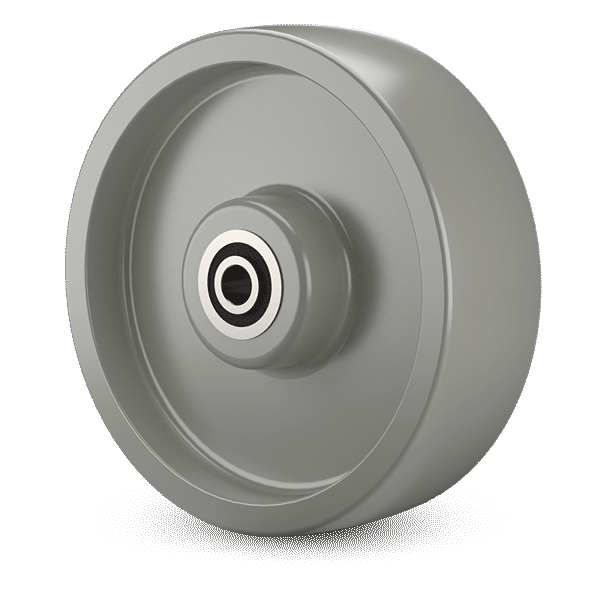

![Envirothane Wheel: W-7006-UGW [Grey]](https://algood-casters.com/wp-content/uploads/2023/04/Algood_Renders-Envirothane-W-7006-UGW-1.png)

![Envirothane Wheel: W-0830-U [Black]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Wheel-3-Envirothane-W-0830-U-.25.png)

![Envirothane Wheel: W-7006-U [Red]](https://algood-casters.com/wp-content/uploads/2023/11/Algood-Wheel-Envirothane-W-7006-U-1.188-RED.png)

![Envirothane Wheel: W-7006-U [Blue]](https://algood-casters.com/wp-content/uploads/2023/11/Algood-Wheels-Envirothane-W-7006-U-1.188-BLUE.png)

![Envirothane Wheel: W-7006-U [Black]](https://algood-casters.com/wp-content/uploads/2023/11/Algood-Wheels-Envirothane-W-7006-U-1.188.png)