There’s No Substitute for Testing

Testing is the only way to ensure that casters and wheels live up to manufacturers’ claims and specifications. That’s why you need to be well-informed about the testing and validation procedures that are being used to verify the quality and performance of the casters and wheels you are specifying or buying. At Algood, we use a variety of testing protocols to ensure that our products meet the highest standards of performance and durability. Our testing is based on requirements established by the Institute of Caster and Wheel Manufacturers. However, the conditions we subject casters to and the results we consider satisfactory exceed industry standards.

In this issue of CasterU, we provide a guide to the testing we carry out at Algood so that you can feel confident when buying casters and wheels.

Our comprehensive testing regimen is the backbone of our commitment to quality and durability. We adhere to the strictest industry standards, surpassing even the most rigorous requirements of specialized industries. Our testing procedures leave no room for error, ensuring that each caster that leaves our facility is primed for unparalleled performance.

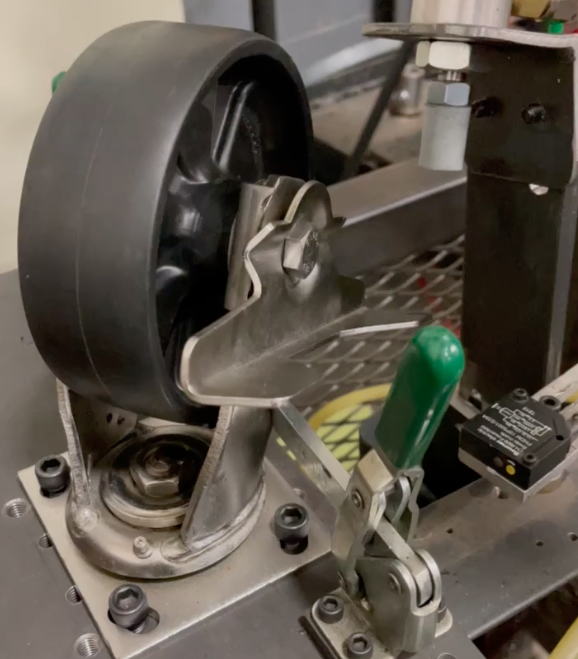

Dynamic Test: Withstanding real-life obstacles

Our dynamic testing replicates real-world conditions, pushing each caster to its limits. Testing at maximum rated load capacity, our casters navigate obstacle courses at varying speeds, undergoing rigorous on-and-off maneuvers. Testing procedures are developed to simulate actual applications by adjusting parameters such as floor conditions (obstacle heights), rolling speed, and run time/rest time. To pass the Algood testing standards, casters with stem mounts must complete a minimum of 500 obstacles, and those with plates must complete 5,000. This comprehensive approach guarantees that every caster can withstand the toughest challenges.

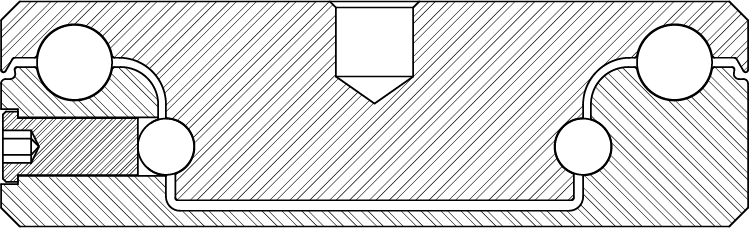

Static Test: Structural stability under load

Structural integrity is paramount in the world of casters. Our static tests assess the maximum weight a caster rig can withstand when it is not in motion, effectively determining the static load capacity of a caster or wheel. This rigorous evaluation allows our customers to accurately and confidently specify the casters and wheels that will meet their requirements.

Thermal Test: Measuring high-temperature performance

Our advanced heat chamber simulates a high-temperature environment in static and dynamic situations. Testing is carried out for casters used in applications such as bakery ovens and autoclaves. The number of temperature cycles without cracking or degradation, is established. Each test cycle takes the caster, loaded at rated capacity, from room temperature to 475 degrees Fahrenheit for one hour and then back to room temperature. Extended tests are carried out at 525ºF for 30 minutes. In addition to ensuring casters will exceed our customers’ needs, we use test results to refine the blend of wheel compounds to further enhance high-temperature performance.

Vertical Impact Test: Determining minimum impact strength

The vertical impact test measures the minimum impact strength of casters. It uses a free-falling weight (or similar force) to test how much impact energy could cause the caster to malfunction or break if an object drops on it. Additionally, all wheels undergo individual impact testing. These tests also validate component-level performance and resistance to deformation under impact.

Testing: Protect your investment

Our comprehensive testing regimen is the backbone of our commitment to quality and durability. We adhere to the strictest industry standards, surpassing even the most rigorous requirements of specialized industries.

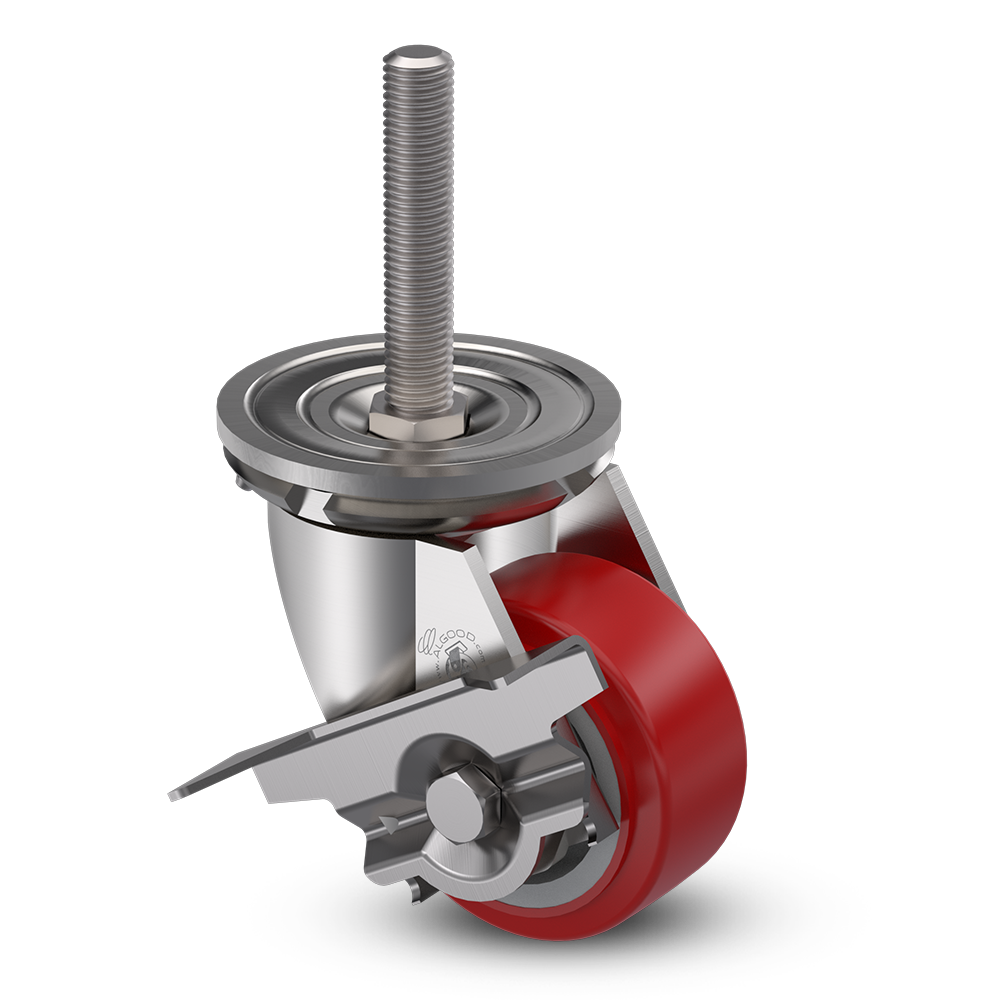

Brake/Locking Fatigue Testing: Stopping on time

The test establishes the durability/fatigue performance of the caster braking/locking device, allowing continuous cycling from the braking to the non-braking position. Requirements are established based on application and performance standards for different braking devices.

Insufficient or substandard testing could result in caster failure, equipment damage, load loss, or even serious injury.

To protect your caster investment, make sure the casters and wheels you specify or buy have been tested using the same demanding Algood standards.

![Cyclone Series: SCY125-A84L-URHX2-TB-UWB-4PSL [Corrosion Resistant Zinc Finish]](https://algood-casters.com/wp-content/uploads/2016/01/Algood-Caster-Cyclone_Series-SCY125-A84L-URHX2-TB-UWB-4PSL.png)

![PurThane Wheel: W-7006-PTN-PB-.5 [Aluminum Core with Black Tread]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Wheel-PurThane-W-7006-PTN-PB-.5.png)

![Tornado Series: STO82-A38H-UGC-PB-UWB-4PSLN [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/02/Algood-Caster-Tornado_Series-STO82-A38H-UGC-PB-UWB-4PSLN.png)

![Twister Series: STW82-A46H-PTNX2-PB-UWB-4PSL [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/02/Algood-Caster-Twister_Series-STW82-A46H-PTNX2-PB-UWB-4PSL.png)

![Tornado Series: STO62-1.000X4-UR-RB-SLB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/02/Algood-Caster-Tornado_Series-STO62-1.000X4-UR-RB-SLB.png)

![Twister Series: STW62-A46H-MAU-RB-SLB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/02/Algood-Caster-Twister_Series-STW62-A46H-MAU-RB-SLB.png)

![6809 Series: S6859-A45H-MPU-RB [304 Stainless Steel]](https://algood-casters.com/wp-content/uploads/2023/07/Algood-Caster-6809_Series-S6859-A45H-MPU-RB.png)

![MAXX9 Series: S6559-A38H-NYNW-RB [304 Stainless Steel]](https://algood-casters.com/wp-content/uploads/2023/07/Algood-Caster-MAXX9_Series-S6559-A38H-NYNW-RB.png)

![7003 Series: S7063-A38H-UR-PB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/05/Algood-Renders-7003_Series-S7063-A38H-UR-PB.png)

![7009 Series: S7069-A38H-NYNW-RB [Stainless Steel Finish]](https://algood-casters.com/wp-content/uploads/2023/05/Algood-Renders-7009_Series-S7069-A38H-NYNW-RB.png)