5000 Series. More Than 5000 Configurations.

When it comes to casters for demanding tasks, most companies provide options. At Algood, we deliver solutions. The 5000 Series was built with one purpose: to deliver a caster you can count on—anytime, anywhere. Trusted across industries from healthcare to warehousing, it’s engineered to handle nearly every application.

Each caster supports 450 lbs., so a four-caster setup easily handles up to 1,800 lbs. That strength, combined with precision engineering, makes the 5000 Series a go-to solution for anything that needs to move—and keep moving. You also get modular flexibility—lots of it.

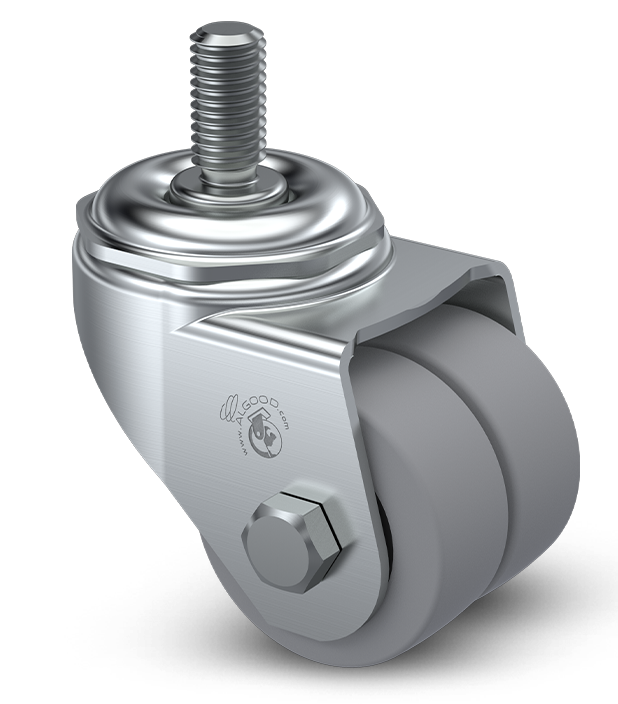

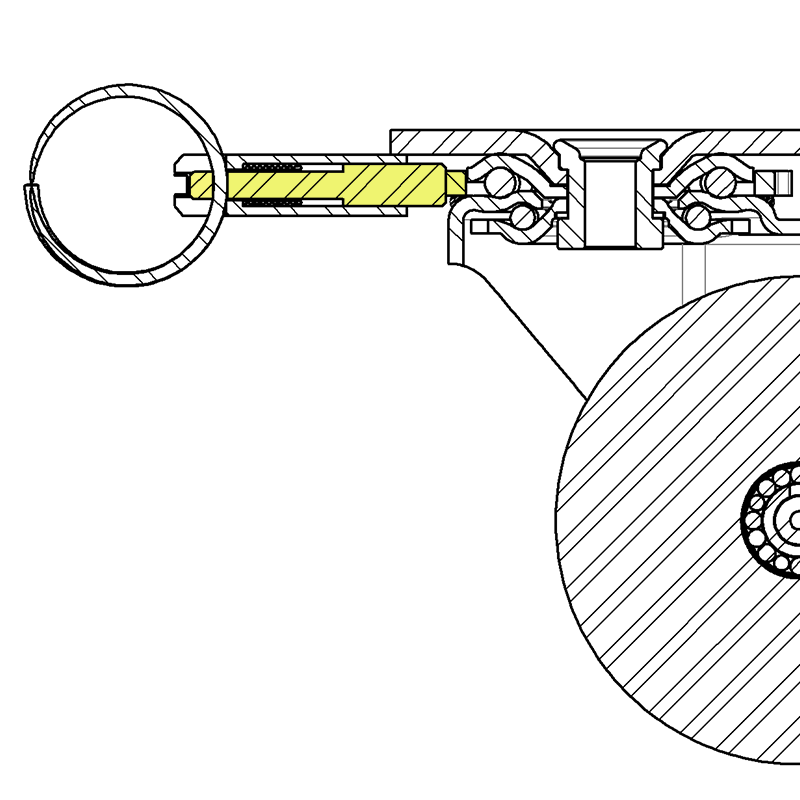

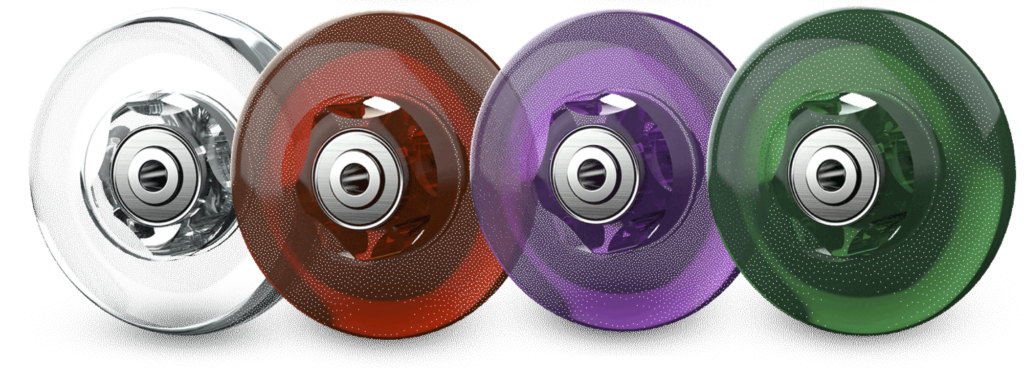

Wheel sizes include 3″, 4″, 5″, and 6″, with tread widths of 1-1/4″ or 1-1/2″. Choose from multiple plate options and stem styles like round, threaded, and expandable. We offer over a dozen wheel materials, including Envirothane™ and ProTech™, plus high-heat options like Lava™. Our exclusive iLock™ brake system ensures stability and control, or you can go with top lock or double lock brakes.

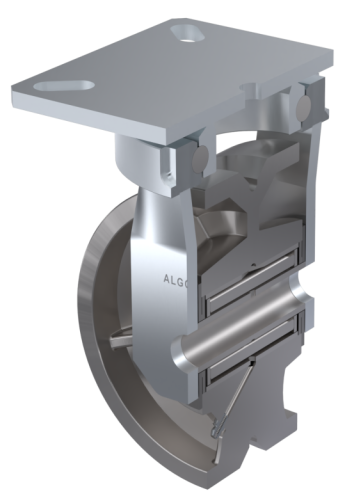

Need even more strength? Step up to the 5400 Series. It holds 700 lbs. per caster—or 2,800 lbs. per cart. It offers the same flexibility, engineering, and North American quality as the 5000 Series, just with more muscle.

The 5000 and 5400 Series are made right here in North America. Every component—yokes, plates, wheels, washers—is manufactured under one roof. We stamp, bend, weld, and mold in-house for full control over quality and delivery. And because they comply with the USMCA, you get seamless cross-border logistics, faster lead times, and dependable supply chain confidence—without compromise.

These casters also clean up well—literally. They’re moisture-resistant, maintenance-free, and NSF-approved. That makes them perfect for food production, pharmaceuticals, medical equipment, and anywhere cleanliness is key. You can also pick from several finishes—chrome, brass, black, zinc—to match your environment or branding.

At Algood, we don’t just sell casters—we help you solve equipment challenges. Whether you need something simple or fully custom, our team will help you find the right fit. And you’ll always talk to someone who knows exactly how your caster should perform. Whether you need ten or ten thousand, we deliver with consistent lead times and with our 3-year No-Excuse Warranty, reinforcing the trust customers have placed in Algood for generations.

Algood is proud to manufacture its casters and wheels right here in North America. With our fully integrated manufacturing facility in Toronto, we are leaders in quality and innovation. For more information about Algood Casters, Call: 1-800-254-6633 or Email: Service@Algood.com

![6900 Series: 6906-A46H-SS-RB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/05/Algood-Renders-6900_Series-S6906-A46H-SS-RB.png)

![7100 Series: S7108-A46J-UR-RB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/08/Algood-Casters-7100_Series-S7108-A46J-UR-RB.png)

![7200 Series: S7208-A53J-MR-RB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/08/Algood-Casters-7200_Series-S7208-A53J-MR-RB.png)

![7500 Series: S7506-A53J-LVW-RB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/11/Algood-Casters-7500_Series-S7506-A53J-LVW-RB.png)

![1900 Series: S1953-A27D-PROF-PB-TG [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/08/Algood-Casters-1900_Series-S1953-A27D-PROF-PB-TG.png)

![1900 Series: S1953-A27D-LV [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/10/Algood-Caster-1900_Series-S1953-A27D-LV.png)