Profit vs Quality: Boeing vs Algood

Recent events at Boeing are a cautionary tale for every manufacturer. They bring to life the ever-present tension between quality and profitability. That’s a very narrow path to navigate. Fall on one side, and your financial fortunes suffer. Falling on the other side puts your reputation – and, in the case of Boeing, lives at risk. Here are some thoughts about what really happened at Boeing and why I believe we’re doing a better job of managing the quality-profitability divide at Algood.

In January, a fuselage panel blew out on an Alaska Airlines Boeing 737 Max 9. The rapid loss of cabin pressure pulled the clothes off a child and caused oxygen masks to drop from the ceiling, but miraculously, none of the 171 passengers and six members were injured. This incident set off a mass investigation and the grounding of all Max 9 jets. Adding to Boeing’s problems, U.S. carriers that fly the Max 9 — reported finding loose bolts and other hardware in other panels, suggesting quality issues with the door plugs were not limited to one plane. Eventually, an investigation concluded that the fuselage bolts were never installed on the Alaskan Air jet and others.

This is about more than a couple of bolts. It’s a complete breakdown of safety procedures. If bolts can be left off a door assembly, who’s to say that they can’t be left off an engine or a wing?

All of this comes on the heels of a major quality lapse in the in-flight control systems that led to two catastrophic crashes in 2018, killing almost 350 people. That resulted in Boeing agreeing to pay $2.5 billion to settle a Justice Department investigation, admitting that employees misled regulators about the safety of the 737 Max. All Max jets were grounded worldwide for nearly two years.

You would have thought that Boeing would have learned its lesson. But almost unbelievably, that isn’t the case. Maybe that’s why the CEO of Alaska Air said, “I am more than frustrated and disappointed. I am angry. My demand on Boeing is, what are they going to do to improve their quality programs in-house?”

So, here’s what I believe to be the problem. The people at the top at Boeing are all finance guys. The current CEO, whose predecessor was fired because of the previous fatal quality issues, is a former Blackstone executive and rose through the ranks of accounting and finance. And clearly, he hasn’t turned the company around. For a company like Boeing, safety and quality must come first and the bottom line second.

There is always tension between meeting financial goals and maintaining quality and safety standards. But when those in charge are only concerned about the next quarter, it has a cascading impact on training, assembly, designers, engineers, and quality assurance. There needs to be a culture shift at Boeing.

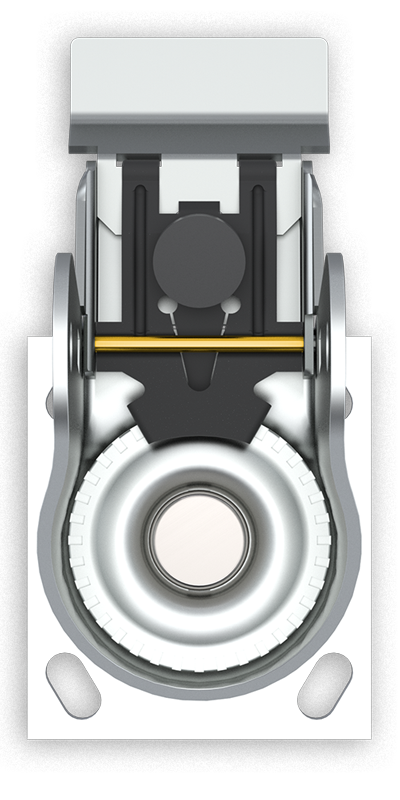

Corporate ownership exacerbates the tension because the measure of success demanded by shareholders is always financial – even if it comes at the expense of quality. In an owner-managed operation like Algood, we have the freedom to proudly stand behind every caster and every wheel that leaves our fully integrated manufacturing facility.

No manufacturer is immune from quality assurance challenges. What sets companies apart is the way they deal with them. Many years ago, we had a major problem with our high-temperature wheels. When we discovered they were not meeting quality standards, we shut down the production program. Completely. In a day. We probably forfeited well into six figures in sales over six to eight months. We understood there was a failure, and the wheel material was not performing.

We started from scratch, re-developing a compound to meet the requirements. In fact, we created our own testing lab to ensure that the wheels functioned perfectly within the specified temperature range. We weren’t going to sell a product unless we were completely confident. It took nine months to perfect, but we haven’t had a single wheel fail since then. Interestingly, we’ve also tested many of our competitor wheels only to discover that many don’t meet industry standards.

We used to have a customer who would tell us that “quality is free.” In other words, he wasn’t willing to pay anything extra for quality. The reality is that there is a cost to quality. If you buy North American-made casters and wheels, you understand there is also value in that quality. Customers always want to pay less, and there are always ways of cutting costs. But there is a limit at some point because you have to believe in the quality of the product you’re selling.

At Algood, our QA and Engineering teams take the lead on product development, and I’m proud to listen to them. If they’re not satisfied, I’m not satisfied, and we’re not bringing that product to market. If the costs are too high, we’ll look for a way to produce a high-quality product at a more reasonable price point. But our customers understand that Algood’s quality is worth the peace of mind it comes with.

Dare I say that if Boeing were a little more like Algood, they would be flying a lot higher.

![6809 Series: S6859-A45H-MPU-RB [304 Stainless Steel]](https://algood-casters.com/wp-content/uploads/2023/07/Algood-Caster-6809_Series-S6859-A45H-MPU-RB.png)

![MAXX9 Series: S6559-A38H-NYNW-RB [304 Stainless Steel]](https://algood-casters.com/wp-content/uploads/2023/07/Algood-Caster-MAXX9_Series-S6559-A38H-NYNW-RB.png)

![7003 Series: S7063-A38H-UR-PB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/05/Algood-Renders-7003_Series-S7063-A38H-UR-PB.png)

![7009 Series: S7069-A38H-NYNW-RB [Stainless Steel Finish]](https://algood-casters.com/wp-content/uploads/2023/05/Algood-Renders-7009_Series-S7069-A38H-NYNW-RB.png)

![6500 Series: S6563-A38H-RXW-RB-TG-ALK [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/08/Algood-Casters-6500_Series-S6563-A38H-RXW-RB-TG-ALK.png)