Twister™: Heavy-Impact Performance for Real World Abuse

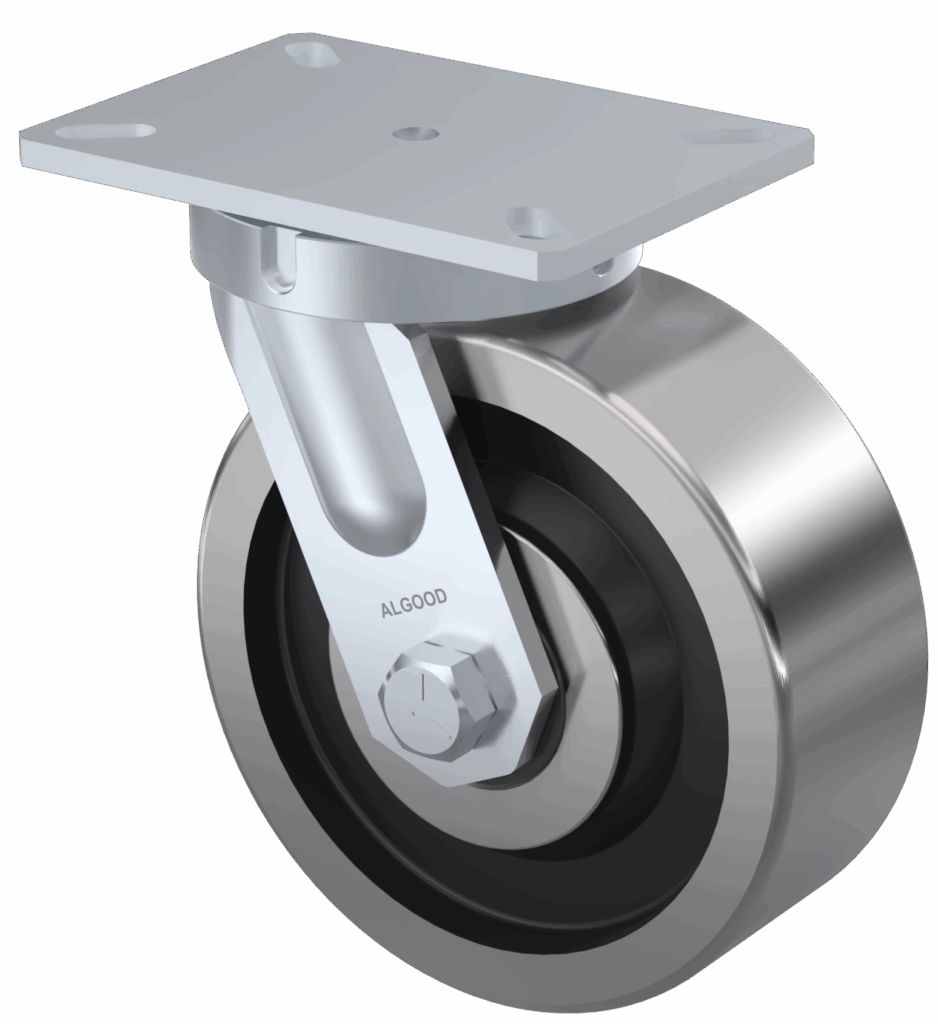

The Twister™ Series is a kingpinless caster engineered for high-impact applications where equipment is pushed hard and reliability is non-negotiable. The Twister™ is built to withstand abusive conditions and tolerate major shifts in cargo loads, without compromising the structural strength that keeps your team moving safely and efficiently.

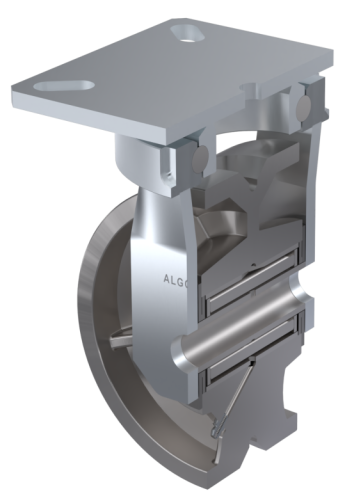

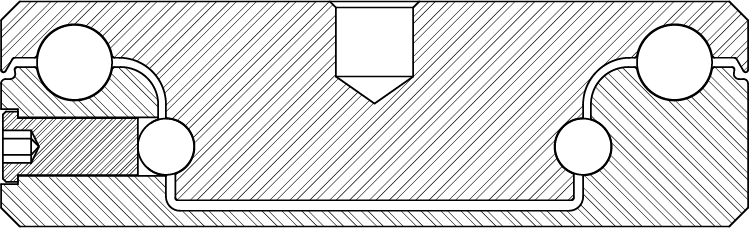

The Twister™ achieves its performance through purposeful engineering, starting with uniquely reinforced leg construction. Its heavy-gauge steel legs are 2-1/2” wide and 1/4” thick, wrapped around the head for added stability under impact and side-loading forces. With double welding and a deeper emboss that work-hardens the forks, Twister™ is designed to hold its integrity in applications where standard casters can deform, loosen, or fail prematurely.

At the head, the design includes a single ball raceway and is robotically welded directly to the plate, creating a rigid, high-strength assembly built to take repeated punishment. Add full heat treatment, and you get a caster that delivers consistent performance over the long haul. It’s ideal for heavy equipment and demanding environments, like automotive, manufacturing plants, tow lines, and industrial platform trucks.

This heavy-duty caster is manufactured in our fully integrated facility in Toronto. That means you get outstanding lead times, dependable delivery dates, and trusted North American workmanship all backed by our 3-Year No Excuse Warranty™.

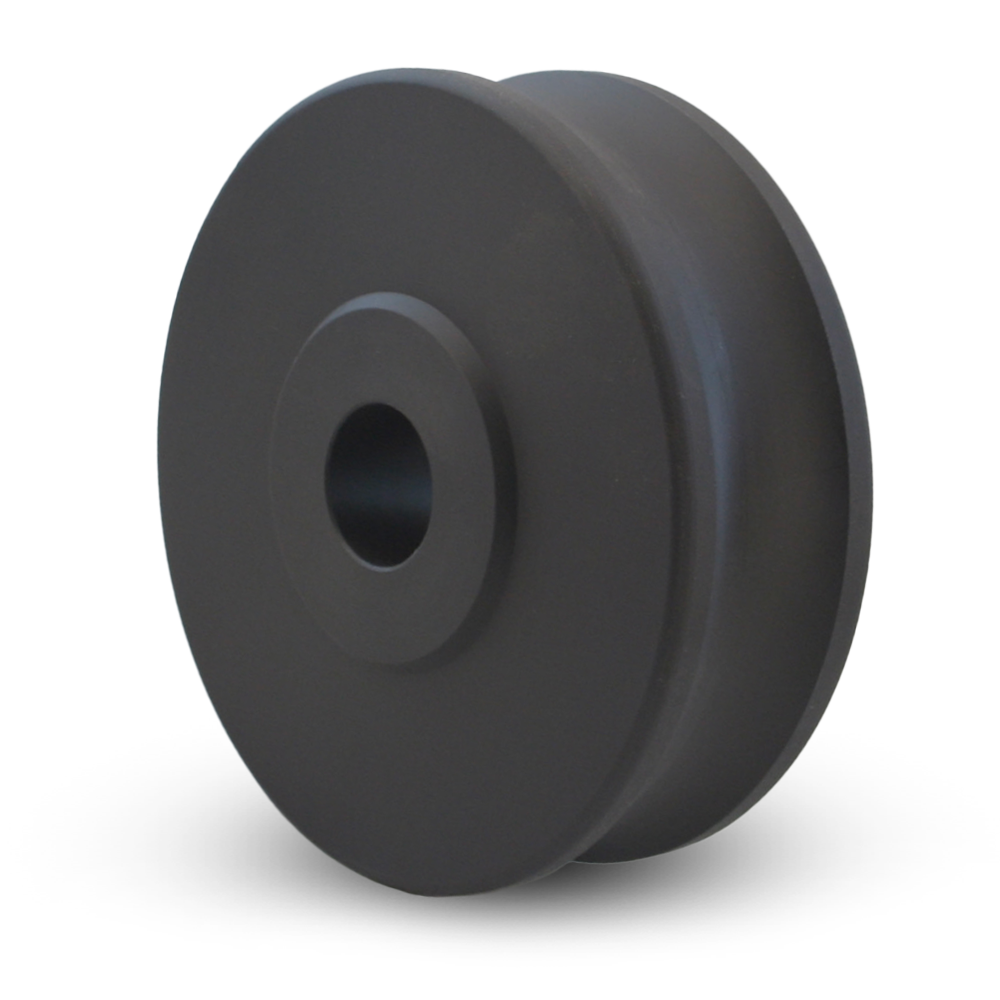

Twister™ also delivers flexibility where it matters most: application fit. With up to 2,000 lbs. of capacity, it can be paired with Algood wheel options like NyRock™, RollX™, and Envirothane™, and is available in 4”, 5”, 6”, and 8” diameters with multiple tread widths. It can also be equipped with several brake, stem, bearing, and plate options. Twister™ casters can even be ordered in a dual wheel configuration or with special overall heights when your build requires a tailored solution.

In heavy-duty environments, a caster isn’t just a component. It’s a critical performance point. If you’re looking for a caster built for abusive, high-impact environments and want the confidence that comes with expert engineering support and precision manufacturing, the Twister™ is ready to take the punishment and keep performing. Find out more about the Twister™ from your local Algood representative or a member of our customer support team.

Algood is proud to manufacture its casters and wheels right here in North America. With our fully integrated manufacturing facility in Toronto, we are leaders in quality and innovation. For more information about Algood Casters, Call: 1-800-254-6633 or Email: Service@Algood.com

![Twister Series: STW82-A40H-LVW-RB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/11/Algood-Caster-Twister_Series-STW82-A40H-LVW-RB.png)

![Twister Series: STW62-A46H-MAU-RB-SLB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/02/Algood-Caster-Twister_Series-STW62-A46H-MAU-RB-SLB.png)

![Twister Series: STW82-A46H-PTNX2-PB-UWB-4PSL [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/02/Algood-Caster-Twister_Series-STW82-A46H-PTNX2-PB-UWB-4PSL.png)

![Cyclone Series: SCY125-A84L-URHX2-TB-UWB-4PSL [Corrosion Resistant Zinc Finish]](https://algood-casters.com/wp-content/uploads/2016/01/Algood-Caster-Cyclone_Series-SCY125-A84L-URHX2-TB-UWB-4PSL.png)

![Tornado Series: STO82-A38H-UGC-PB-UWB-4PSLN [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/02/Algood-Caster-Tornado_Series-STO82-A38H-UGC-PB-UWB-4PSLN.png)

![Tornado Series: STO62-1.000X4-UR-RB-SLB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/02/Algood-Caster-Tornado_Series-STO62-1.000X4-UR-RB-SLB.png)