Healthcare-Inspired AGV Caster Innovation

In today’s fast-paced, technology-driven world, efficiency and reliability are paramount—especially in environments like healthcare, pharmaceuticals, and advanced manufacturing. Automated Guided Vehicles (AGVs) are at the forefront of this movement, streamlining operations and ensuring seamless workflow.

Enter our Hero caster which is exclusively designed for AGV (Automated Guided Vehicle) applications. In fact, it was originally developed to meet the needs of Canada’s first fully computerized hospital. AGV applications have unique requirements and the features of our Hero meet all of them.

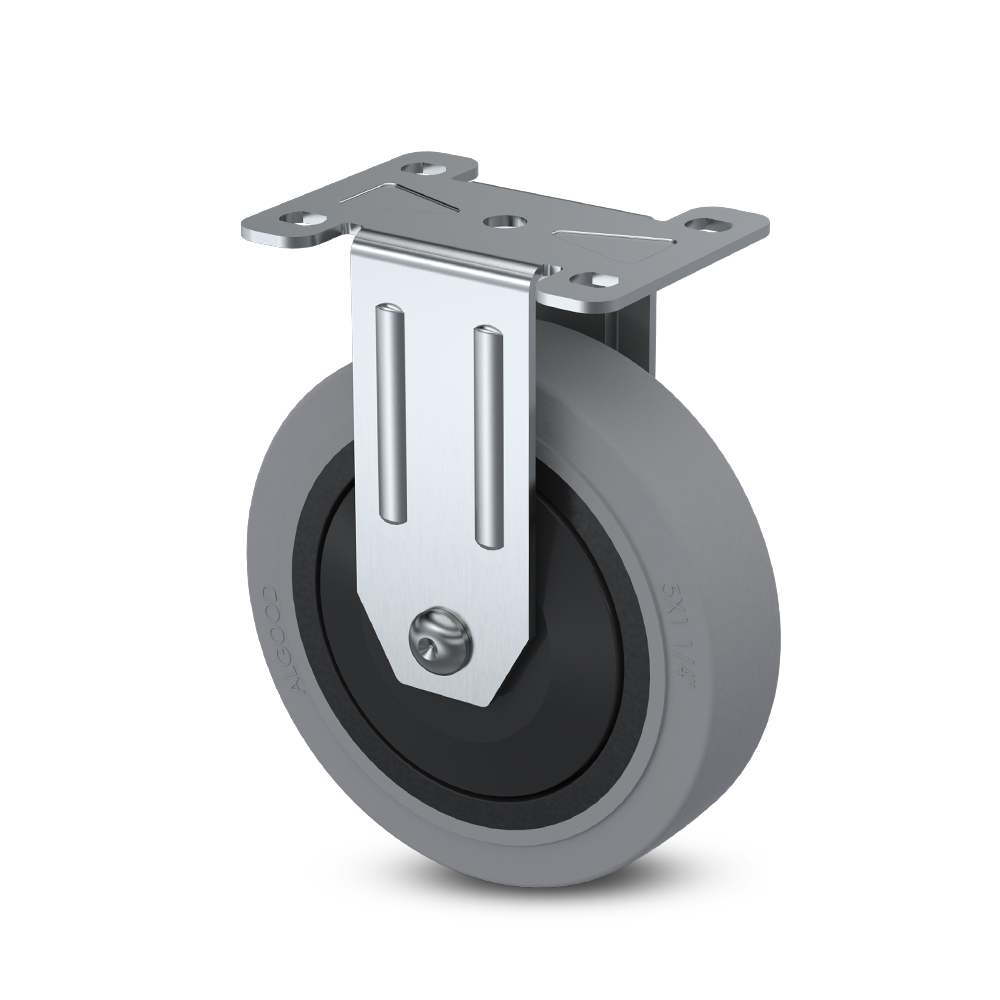

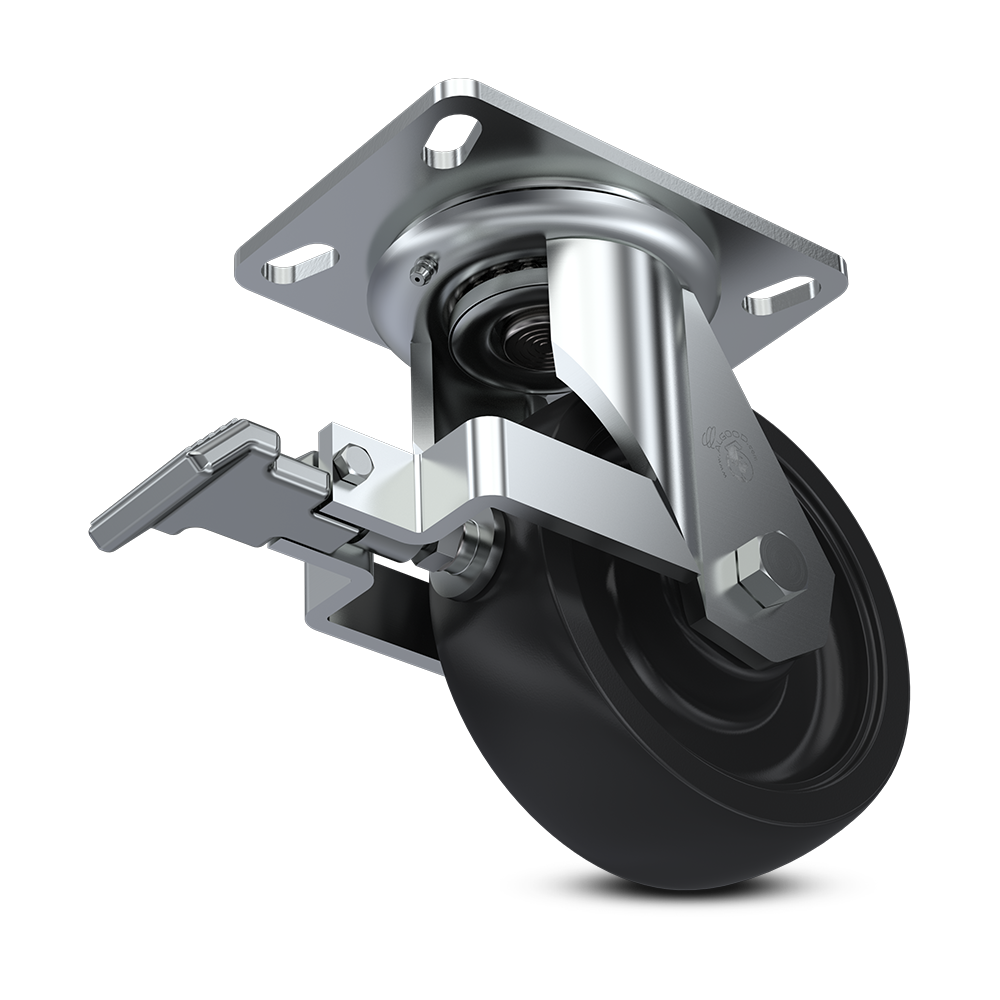

The Hero is a 6” X 1 1/4” fully stainless steel caster that features a sealed ball bearing in the head locked in with the kingpin.

Because AGV equipment frequently travels on metal tracks, the Hero has been designed with an auto align function. A pivoting ball bearing allows the swivel caster to self lock in both the trail and the lead position. A rigid version of the caster is also available.

Its stainless steel construction, makes Hero suitable for all heathcare, pharmaceutical and technology applications. With a capacity of 500 lbs., it can accommodate all AGV chassis and carts.

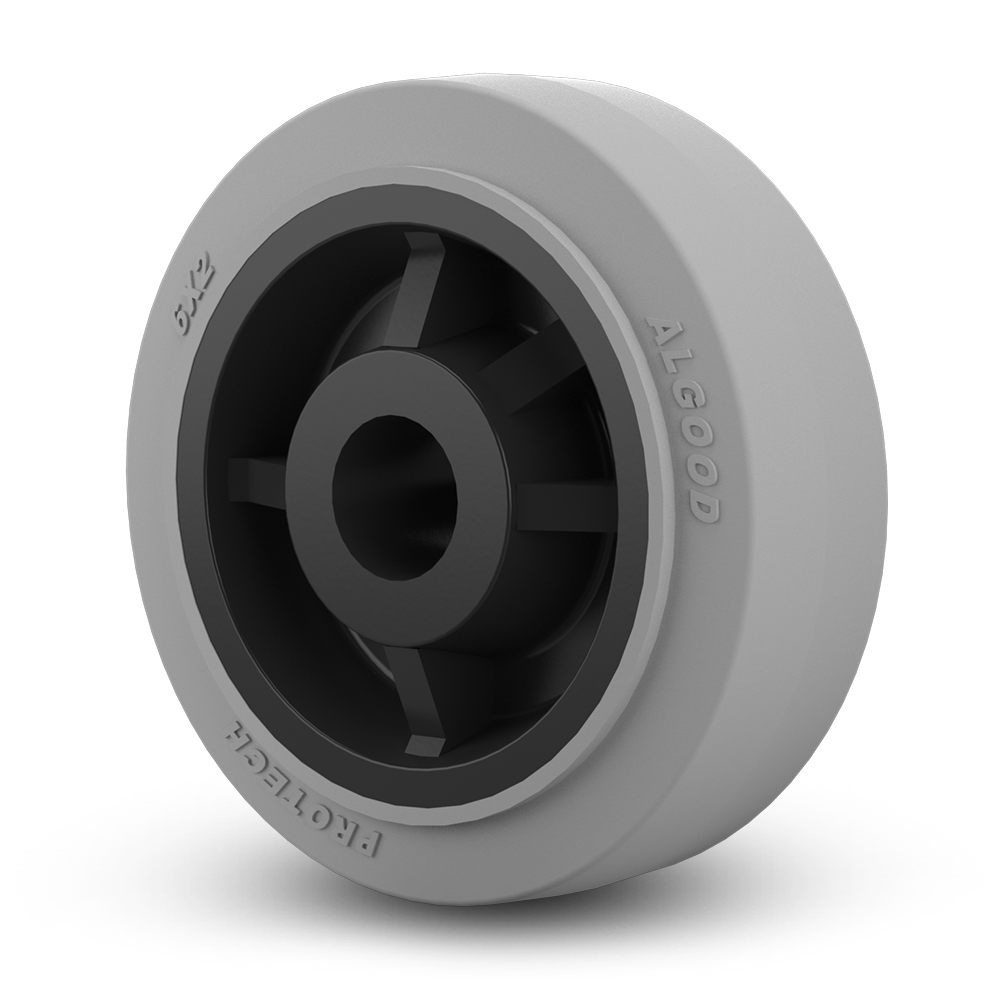

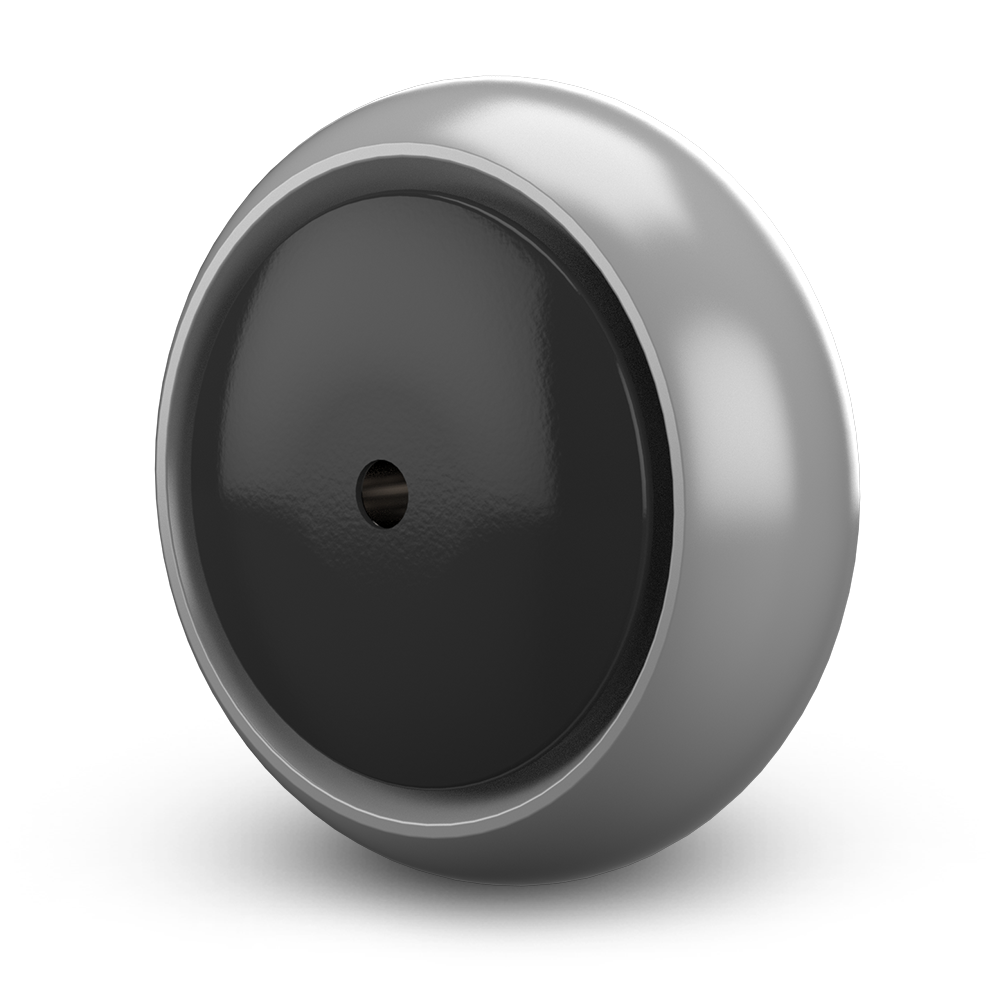

These casters are exclusively equipped our Envirothane™ wheels because they are perfect for AGV applications. With a durometer of 65D, Envirothane wheels are durable enough to travel in AGV tracks. At the same time the proprietary urethane compound is but soft enough to be quiet and non marking when in other areas. Envirothane is moisture and chemical resistant allowing it to withstand wash-down environments and its one-piece construction makes it maintenance free.

Hero casters are manufactured in our fully integrated plant in Toronto. That means you get remarkable lead times, delivery dates you can count on and superb North American quality backed by our 3-Year No-Excuse Warranty.

The Hero is perfectly designed for AGV applications, making it unique in the industry. If you are looking for the right casters for AGV equipment, contact your local Algood representative or contact a member of our customer service team. Don’t settle for less—equip your AGVs with Algood’s Auto Align Caster, the industry’s true healthcare hero.

Algood is proud to manufacture its casters and wheels right here in North America. With our fully integrated manufacturing facility in Toronto, we are leaders in quality and innovation. For more information about Algood Casters, Call: 1-800-254-6633 or Email: Service@Algood.com

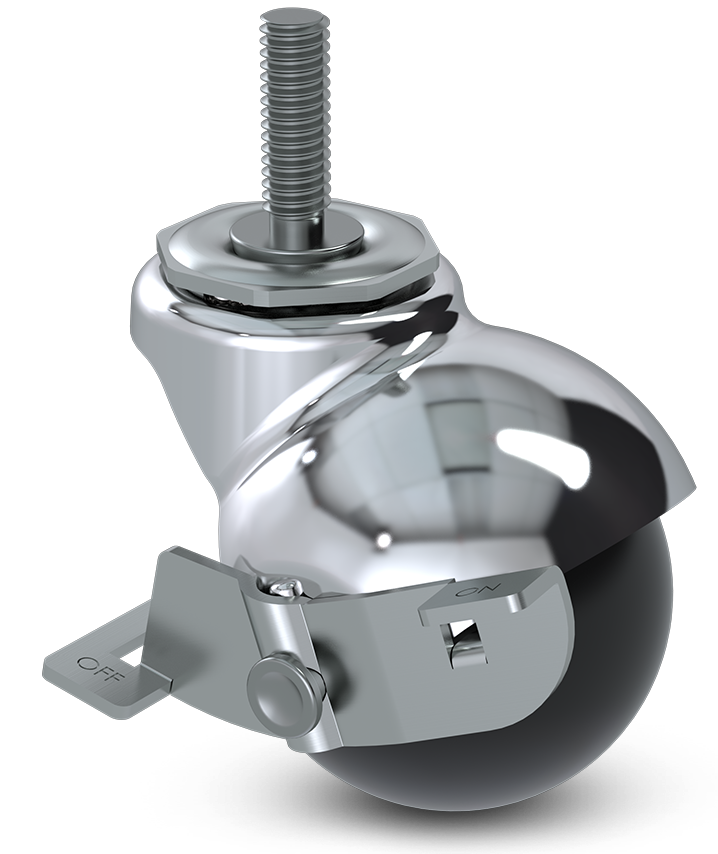

![5000 Series: S5053-A27D-HTPH [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/10/Algood-Caster-5000_Series-S5053-A27D-HTPH.png)

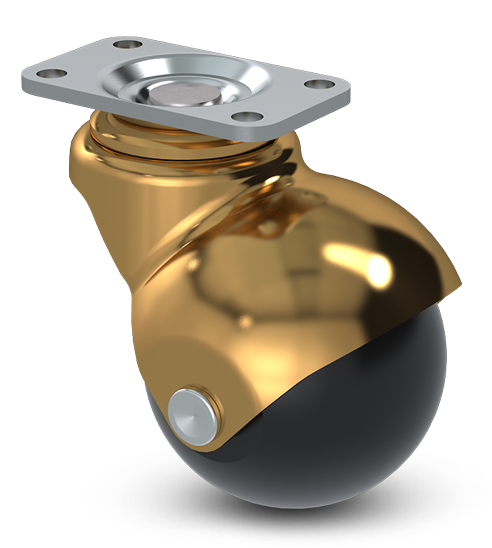

![5000 Series: S5053-A27D-PLY-PB-TG-iLK [Zinc]](https://algood-casters.com/wp-content/uploads/2023/05/Algood-Renders-5000_Series-S5053-A27D-PLY-PB-TG-iLK.png)

![NyRock Wheel: W-7006-NYX-PB-1/2 [Black]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Wheel-NyRock-W-7006-NYX-PB-.5.png)

![NyRock Wheel: W-7006-NYXCC-PB-1/2 [Black]](https://algood-casters.com/wp-content/uploads/2024/07/Algood-Wheel-NyRock-W-7006-NYXCC-PB-.5.png)

![7000 Series: S7006-A38H-UG-RB-SLB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2024/07/Algood-Caster-7000_Series-S7006-A38H-UG-RB-SLB.png)

![MAXX™ Series: SE6563-A38H-RXW-RB-TLB2 [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/08/Algood-Casters-6503_Series-S6563-A38H-RXW-RB-TLB2.png)

![MAXX™ Series: SE6563-A38H-RXW-RB-TG-iLK [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/08/Algood-Casters-MAXX_Series-S6563-A38H-RXW-RB-TG-iLK.png)

![2309 Series: S2359-A27D-HTPH-DLB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/10/Algood-Caster-2309_Series-S2359-A27D-HTPH-DLB.png)

![Envirothane Wheel: W-7006-UGW [Grey]](https://algood-casters.com/wp-content/uploads/2023/04/Algood_Renders-Envirothane-W-7006-UGW-1.png)

![Envirothane Wheel: W-0830-U [Black]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Wheel-3-Envirothane-W-0830-U-.25.png)

![Envirothane Wheel: W-7006-U [Red]](https://algood-casters.com/wp-content/uploads/2023/11/Algood-Wheel-Envirothane-W-7006-U-1.188-RED.png)

![Envirothane Wheel: W-7006-U [Blue]](https://algood-casters.com/wp-content/uploads/2023/11/Algood-Wheels-Envirothane-W-7006-U-1.188-BLUE.png)

![Envirothane Wheel: W-7006-U [Black]](https://algood-casters.com/wp-content/uploads/2023/11/Algood-Wheels-Envirothane-W-7006-U-1.188.png)

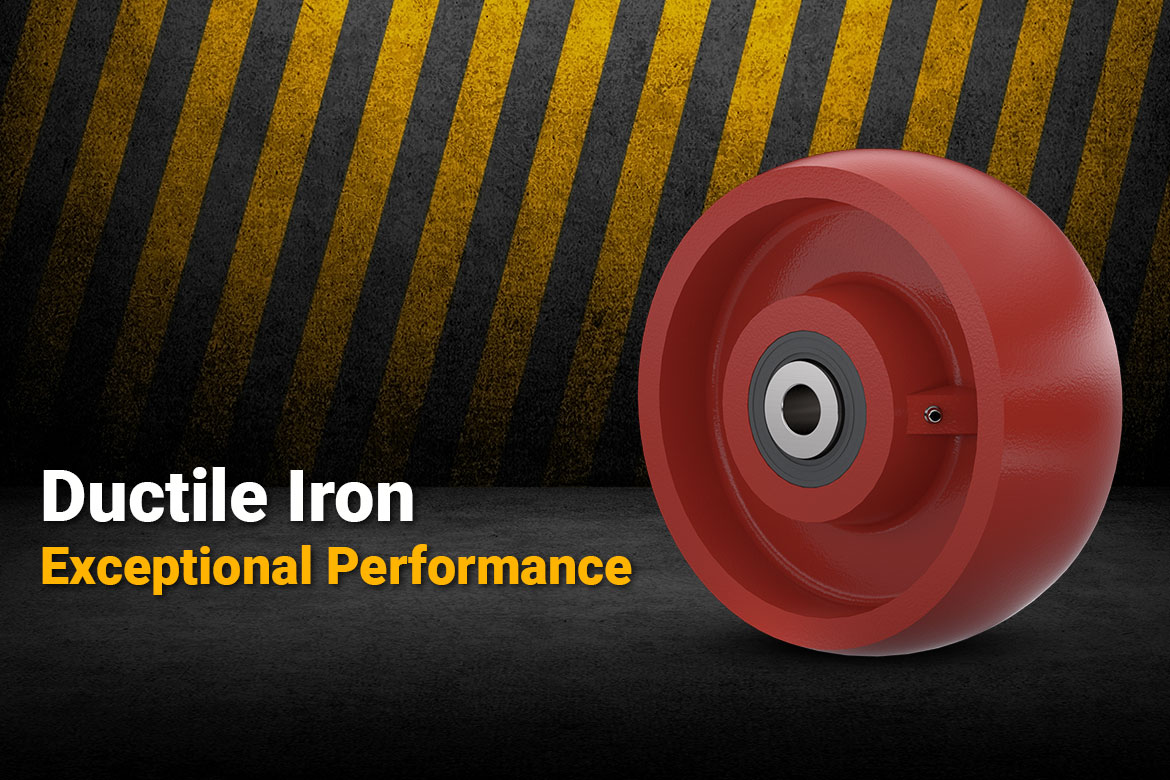

![Ductile Iron Wheel: W-9108-DI-TB-.75 [Red]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Wheel-Ductile_Iron-W-9108-DI-TB-.75.png)

![Crowned Ductile Iron Wheel: W-9108-DIC-TB-.75 [Red]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Wheel-Ductile_Iron_Crowned-W-9108-DIC-TB-.75.png)