Engineered for Heavy Duty Performance: Envirothane™ HD

When a wheel becomes a bestseller, many caster manufacturers would let it ride. But at Algood, engineering momentum matters—because your operating reality keeps changing. Loads increase. Equipment gets more expensive. Downtime becomes less tolerable. And components need to work harder in tighter, tougher environments.

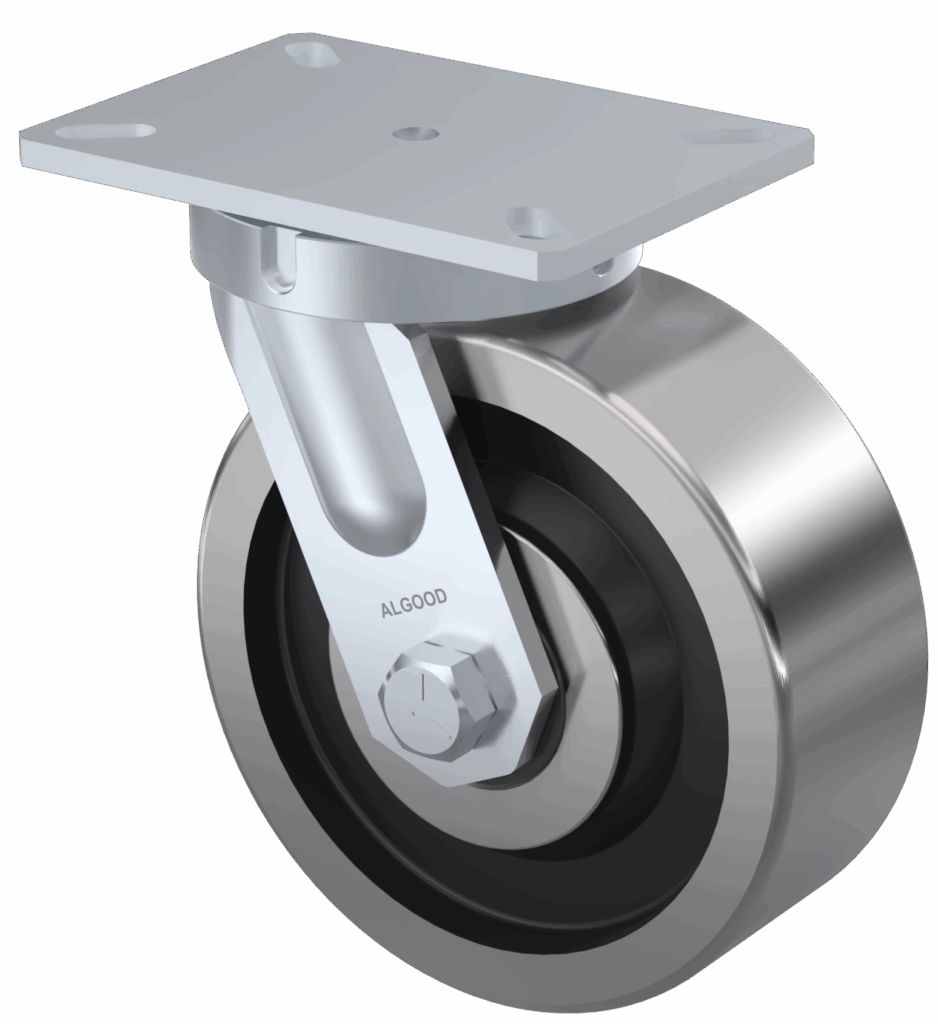

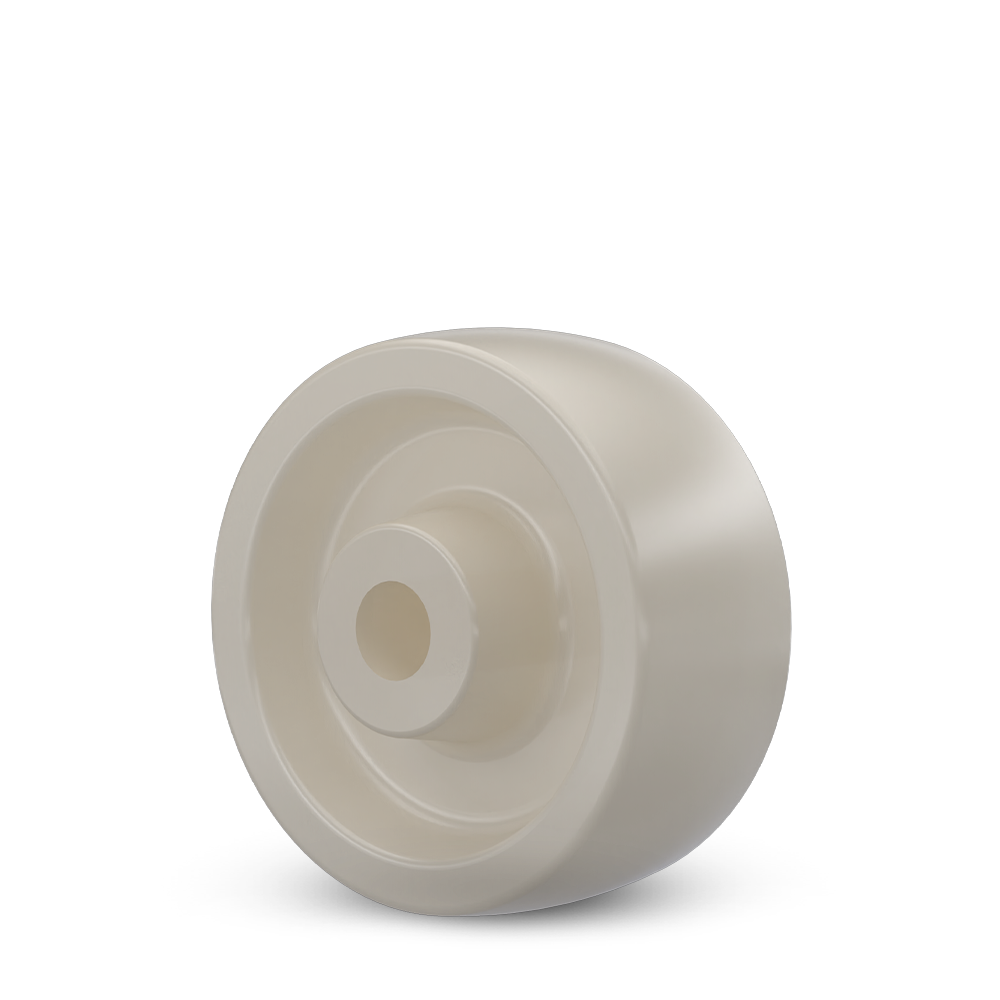

That’s why we took the winning formula behind our original Envirothane™ wheel, known for its one-piece construction and outstanding performance, and re-engineered it to meet new requirements: higher capacity, broader application use, and compatibility with our kingpinless caster platforms. The result is Envirothane HD™—built to help operations teams protect uptime while giving engineers the design characteristics they want.

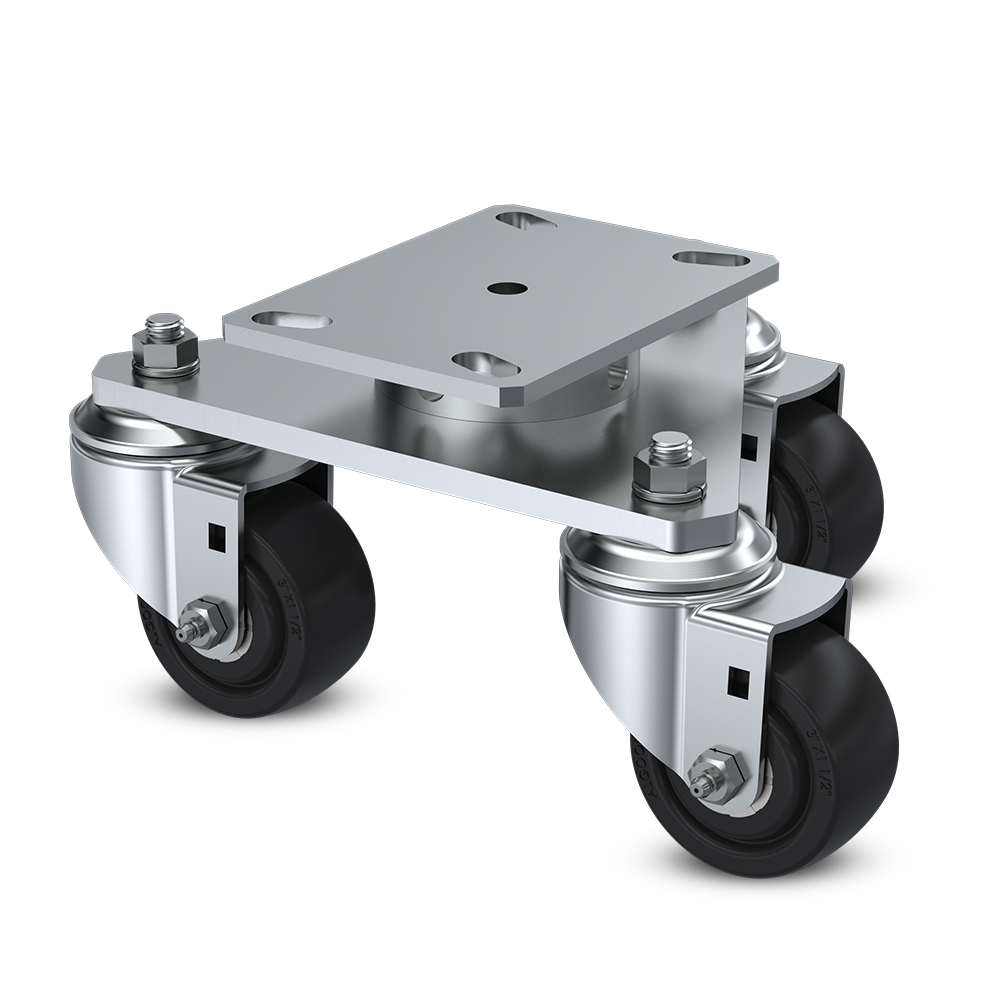

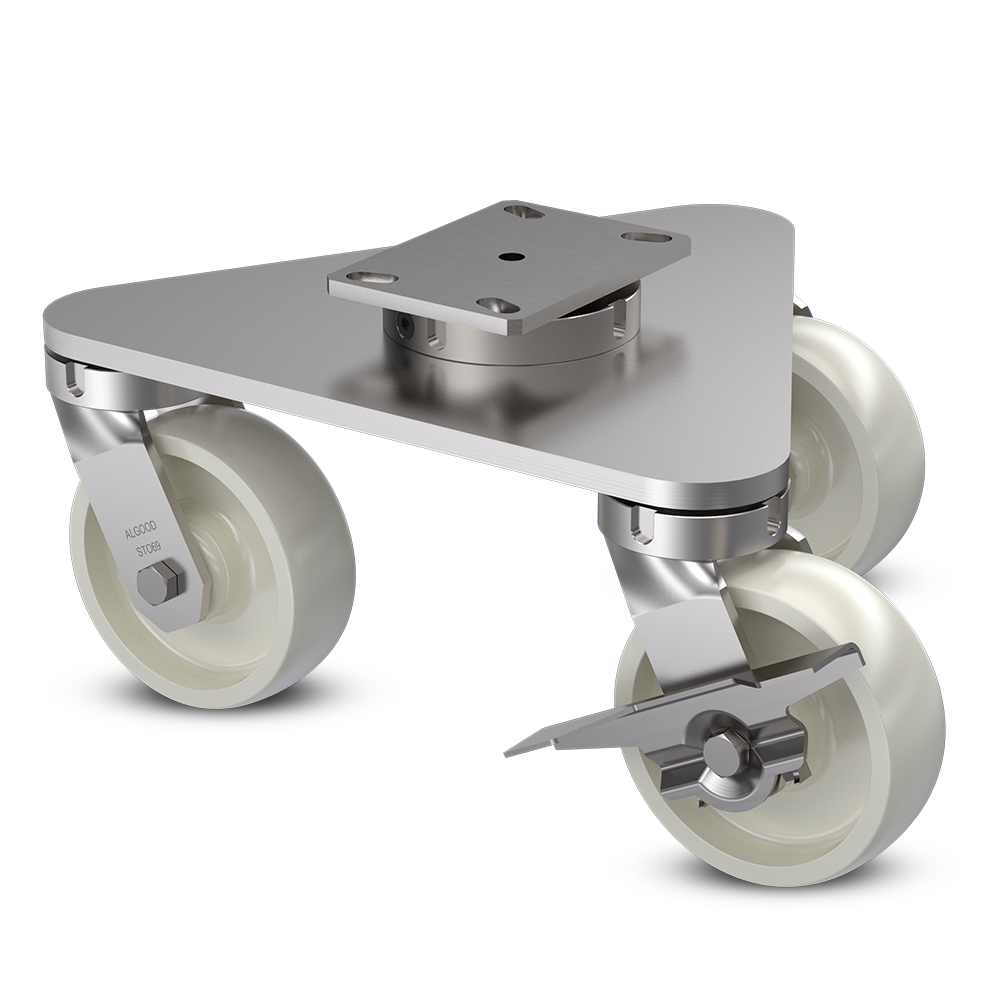

Envirothane HD is engineered for up to 3,600 lbs of capacity while maintaining outstanding maneuverability, making it an ideal match for our Tornado™, Tornado9™, Twister™, and Typhoon™ kingpinless casters. It’s designed to perform indoors or outdoors, protect floors, and stay reliable with maintenance-free operation—so your team can focus on throughput, not wheel upkeep.

All production for this high-performance wheel takes place at our fully integrated manufacturing facility in Toronto. You get competitive lead times and dependable delivery dates, with North American-quality backed by our 3-Year No Excuse Warranty™.

Engineering features with real operational payoff

Here are the design and material choices behind Envirothane HD—and why they matter in the field:

- Injection moulded, one-piece construction to help eliminate core separation, providing durability you can count on

- Sizes that spec easily: 3” to 12” diameters with 2″, 2-1/2”, and 3″ tread widths

- Non-marking for better facility appearance and floor care outcomes

- 80D durometer with memory retention to help prevent flat spotting (especially helpful after static loading)

- Moisture-friendly and chemical-resistant for environments that punish standard wheel materials

- Fully compatible with stainless steel casters

- Temperature range: -45ºF to 200ºF, supporting outdoor use and temperature swings

- NSF approved and pairs well with stainless steel casters for hygiene-sensitive applications

- 100% recyclable, supporting more responsible material choices

- Crowned tread to increase maneuverability (particularly useful when loads are high)

- Maintenance-free, long-lasting, helping extend the service life of equipment

We encourage teams to use our CAD LAB modelling platform to build an Envirothane HD solution that matches your application needs—wheel size, tread width, caster pairing, and more—and then render that configuration in the format that is best for you. For buyers and operations leaders, you can get the right wheel quickly, without back-and-forth, while engineers get about clean selection, correct geometry, and compatibility.

Envirothane HD is suitable for a wide range of applications, including harsh and abrasive conditions, and supports operations across:

- Pharmaceutical, healthcare, food production, hospitality, and high-tech environments

- Heavy material handling, factory settings, and towline applications

If you’re balancing load capacity, maneuverability, floor protection, and long-term durability, Envirothane HD is built for that exact trade space.

Algood is proud to manufacture its casters and wheels right here in North America. With our fully integrated manufacturing facility in Toronto, we are leaders in quality and innovation. For more information about Algood Casters, Call: 1-800-254-6633 or Email: Service@Algood.com

![SL6803 Series: SSL6863-A47H-RXW-PB-TG-iLKW-C [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/07/Algood-Caster-SL6803_Series-SSL6863-A47H-RXW-PB-TG-iLKW-C.png)

![SL7003 Series: SSL7064I-A38H-PTN-PB-iLKW-A [Black Ionic Finish]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Caster-SL7003-SSL7064-A38H-PTN-PB-iLKW-A.png)

![Twister Series: STW82-A40H-LVW-RB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/11/Algood-Caster-Twister_Series-STW82-A40H-LVW-RB.png)

![Twister Series: STW62-A46H-MAU-RB-SLB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/02/Algood-Caster-Twister_Series-STW62-A46H-MAU-RB-SLB.png)

![Twister Series: STW82-A46H-PTNX2-PB-UWB-4PSL [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/02/Algood-Caster-Twister_Series-STW82-A46H-PTNX2-PB-UWB-4PSL.png)

![Polyolefin Wheel: W-7006-POX-1.188 [Black]](https://algood-casters.com/wp-content/uploads/2023/06/Algood-Wheels-Polyolefin-W-7006-POX-1.188.png)

![Office Meister: SOM34I-437SX1-PTN-PB-TG [Black Ionic Finish]](https://algood-casters.com/wp-content/uploads/2023/07/Algood-Caster-The_Office_Meister-SOM34I-437SX1-PTN-PB-TG.png)

![0700 Series: S0722-437SX1-ICEB-PB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/08/Algood-Casters-0700_Series-S0722-437SX1-ICEB-PB.png)