Tornado9™: A Storm of Stainless Steel Strength

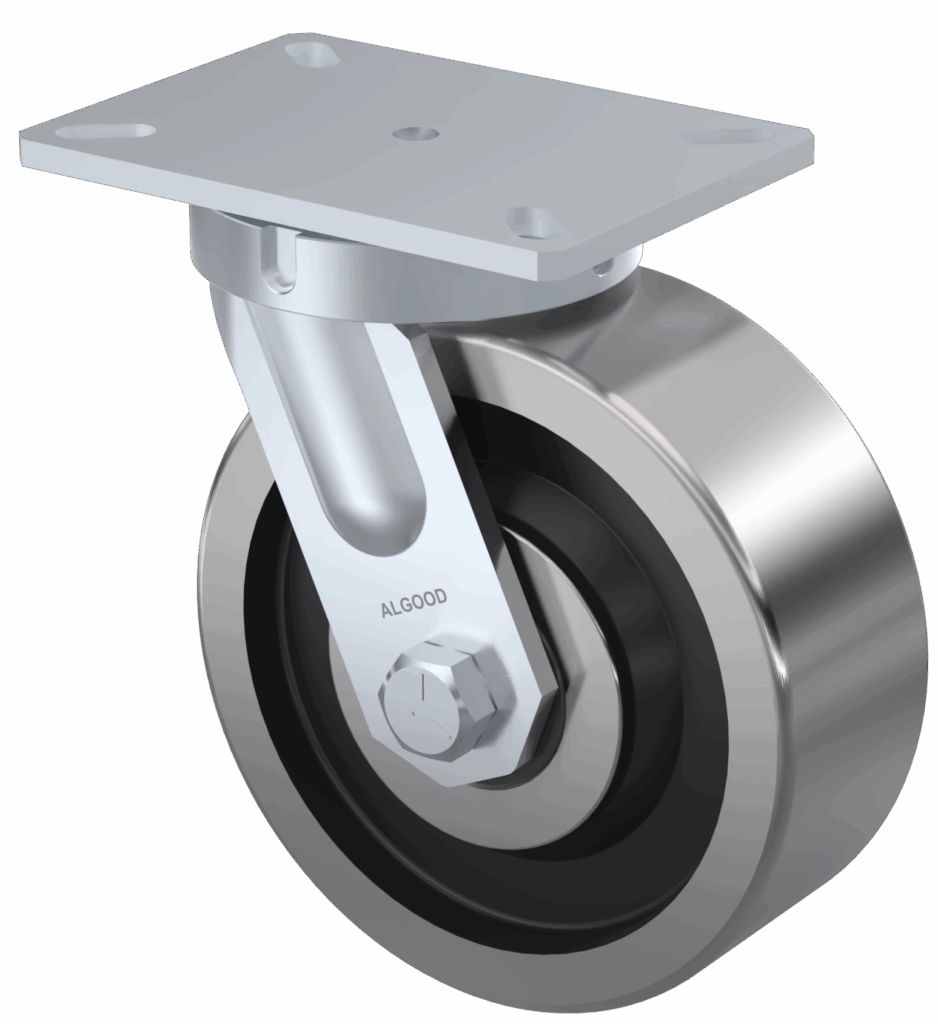

Combining North American-made stainless steel with a kingpinless design, the Tornado9™ doesn’t just meet the challenges of heavy-duty, hygienic, and high-performance environments; it creates a storm of advantages and possibilities.

The Tornado9 is forged from SAE 304 stainless steel that’s work-hardened, electro-polished, de-magnetized, and de-burred. Robotically welded and NSF certified, it stands up to intense pressure, extreme conditions, and unforgiving environments. With a capacity of up to 1,500 lbs, it’s virtually indestructible: the only way to break it is to break the weld or the balls in the raceway.

From hospitals to industrial tow lines, the Tornado9 shines where cleanliness, reliability, and strength are essential. It’s ideal for:

- Hospitals and healthcare environments

- Pharmaceutical and food processing facilities

- Moisture-prone or bacteria-free clean spaces

- High-tech manufacturing

- Tow lines, industrial platform trucks and heavy-duty stock carts

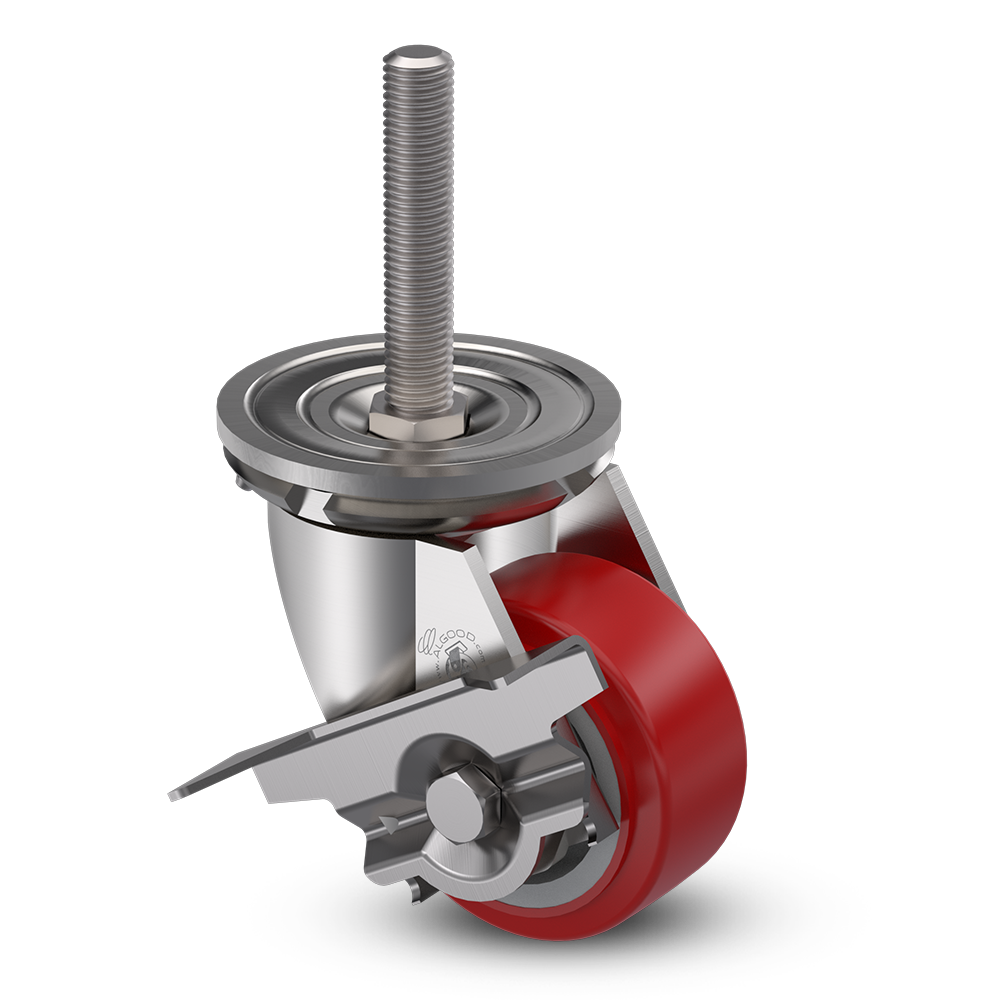

Available in 4” to 8” diameters and available with a wide variety of stems and plates, the Tornado9 fits your application without compromise. You can make it a complete stainless solution with stainless steel roller bearings, spanner bushings and stainless steel side washers.

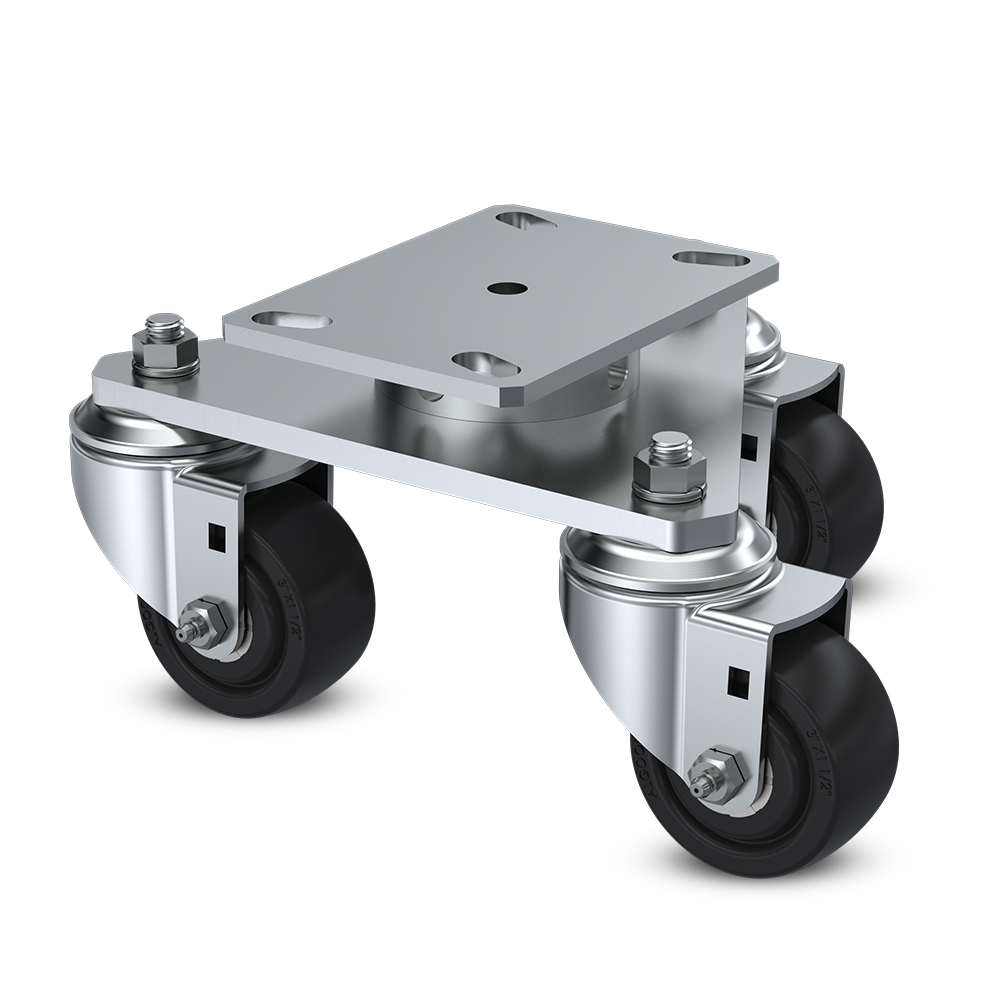

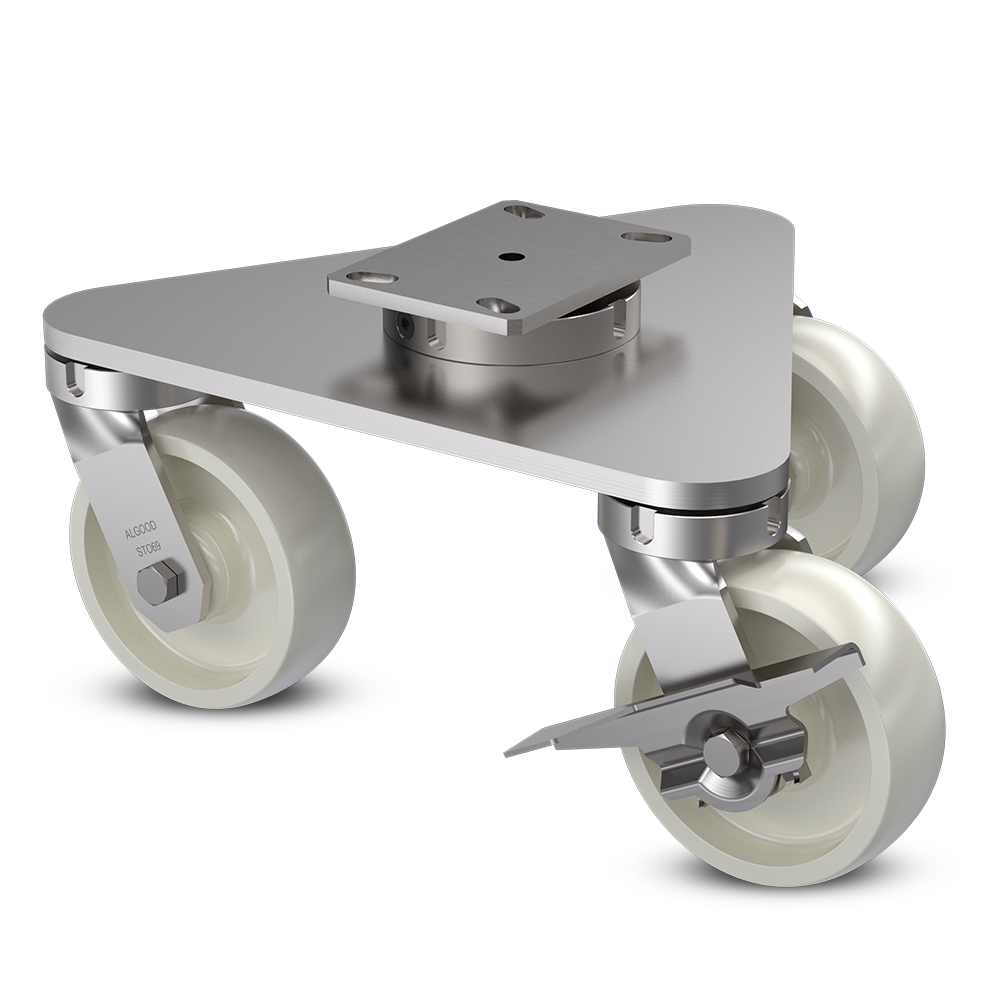

If you need extra capacity, check out the available dual-wheel configurations and custom overall heights.

The Tornado9 delivers a quiet, smooth rotation ride. A high-precision screw plug in the raceway eliminates the need for welding while ensuring torque is just right—never too much or too little. With optional brakes (including side-locking, thumb screw, and swivel lock) and multiple bearing types, the Tornado9 adapts to your needs while maintaining superior maneuverability.

With our CAD LAB design space, you can engineer the Tornado9 configuration to meet your application needs down to the last detail. Choose your wheel type, stem style, brake option, and dimensions. The Tornado9 isn’t just built for performance—it’s built for your performance.

Every Tornado9 caster is built in our fully integrated Toronto facility. That means faster lead times, dependable delivery, and North American quality you can trust. And with our 3-Year No-Excuse Warranty™, your investment is protected by the same values that go into every Algood product we make: durability, accountability, and pride in our craft.

The Tornado9™ is a bold statement about what Algood stands for: design-focused engineering, customer-centered support, and family values to deliver mobility solutions that move your business forward. All grounded in the belief that strength and precision should never be compromised.

Algood is proud to manufacture its casters and wheels right here in North America. With our fully integrated manufacturing facility in Toronto, we are leaders in quality and innovation. For more information about Algood Casters, Call: 1-800-254-6633 or Email: Service@Algood.com

![2309 Series: S2359-A27D-HTPH-DLB [Zinc Finish]](https://algood-casters.com/wp-content/uploads/2023/10/Algood-Caster-2309_Series-S2359-A27D-HTPH-DLB.png)

![6809 Series: S6859-A45H-MPU-RB [304 Stainless Steel]](https://algood-casters.com/wp-content/uploads/2023/07/Algood-Caster-6809_Series-S6859-A45H-MPU-RB.png)

![MAXX9 Series: S6559-A38H-NYNW-RB [304 Stainless Steel]](https://algood-casters.com/wp-content/uploads/2023/07/Algood-Caster-MAXX9_Series-S6559-A38H-NYNW-RB.png)